Common Mode Chokes in Power Supply Systems: Enhancing Signal Integrity

Common mode chokes (CMCs) are clutch in power supply systems for enhancing signal integrity, especially where noise can corrupt sensitive circuits or radiate into the environment. In these systems—think switch-mode power supplies (SMPS), DC-DC converters, or AC mains—they tackle common mode (CM) noise, the pesky interference that rides in-phase on both power lines. By choking this noise while letting the intended differential mode (DM) power flow, they keep signals clean and systems compliant. Let’s break down how they work here and why they matter.

Role in Power Supply Systems

What’s the Problem?

Couple onto output lines, messing with downstream circuits (e.g., microcontrollers, RF amps).

Radiate via cables, failing EMI/EMC regs (e.g., FCC Part 15).

Back-feed into the input source (e.g., AC mains), polluting the grid.

Power supplies, especially SMPS, generate high-frequency CM noise (kHz to MHz) from fast-switching transistors or diodes. This noise can:

How CMCs Help

CM Noise Suppression: The choke’s high impedance (e.g., 1 kΩ at 100 kHz) blocks noise flowing in the same direction on both lines (live/neutral or +/– DC).

DM Transparency: The desired power current (opposite directions) sees near-zero impedance due to flux cancellation in the core, so voltage delivery stays intact.

Result: Cleaner DC output, less radiated EMI, and happier downstream signals.

Principles in Action

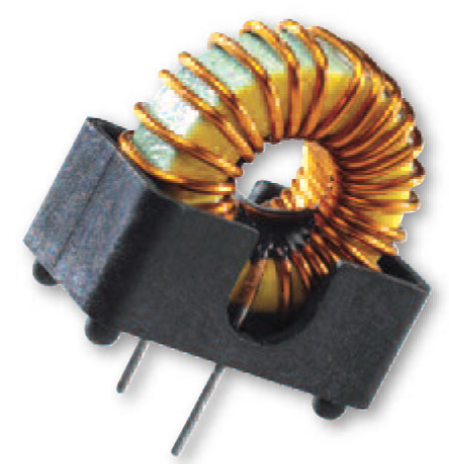

Mechanism: Two windings on a ferrite core (e.g., toroid).

CM currents (noise) reinforce the magnetic field → high LLL, high Z=2πfLZ = 2pi f LZ=2πfL.

DM currents (power) cancel the field → low LLL, low ZZZ.

Example: A 10 mH CMC at 100 kHz offers ~6 kΩ to CM noise but <0.1 Ω to 60 Hz AC or DC power.

Frequency Target: SMPS noise typically spans 10 kHz (switching fundamentals) to 10 MHz (harmonics), so CMCs are tuned here.

Specific Applications in Power Supplies

Input Filtering (AC Mains)

Where: Between AC line and rectifier in an SMPS.

Why: Stops switching noise (e.g., 50 kHz) from escaping back to the grid, meeting CISPR standards.

Example: A 20 mH CMC in a 230 V, 500 W supply cuts CM noise by 30 dB at 100 kHz.

Bonus: Protects against incoming EMI (e.g., lightning transients).

Output Filtering (DC Lines)

Where: Between DC output and load (e.g., 12 V rail to a microcontroller).

Why: Shields sensitive loads from high-freq ripple or CM noise coupled from the switcher.

Example: A 1 mH CMC on a 5 V USB supply kills 1 MHz noise, keeping a connected ADC glitch-free.

Pairing: Often with capacitors (e.g., 0.1 µF to ground) for a full CM filter.

DC-DC Converters

Where: Input or output of a buck/boost converter.

Why: Reduces CM noise from high-speed switching (e.g., 500 kHz) that could radiate via long cables.

Example: A 100 µH CMC in a 48 V-to-12 V automotive converter ensures CAN bus signals stay clean.

Challenge: Must handle high DM current (e.g., 10 A) without saturating.

Inverter Systems (Solar, UPS)

Where: AC output of a DC-to-AC inverter.

Why: Suppresses CM noise from PWM switching (e.g., 20 kHz), preventing EMI radiation.

Example: A 5 mH CMC in a 1 kW solar inverter drops 50 kHz noise by 25 dB, passing EN 61000.

Type: High-current toroid (e.g., 15 A rating).

Ground Loop Mitigation

Where: Between power supply and grounded equipment.

Why: Breaks CM current paths causing 50/60 Hz hum or low-freq noise.

Example: A CMC on a 24 V industrial PSU eliminates hum in a sensor array.

Note: Less about high-freq noise here, more about loop currents.

Enhancing Signal Integrity

Cleaner Power: Reduces voltage spikes or ripple on DC rails, critical for analog circuits or high-speed digital (e.g., DDR memory).

Lower EMI: Cuts radiated noise, protecting nearby RF receivers or comms lines (e.g., Wi-Fi at 2.4 GHz).

Stable Signals: Prevents CM noise from inducing errors in differential pairs (e.g., Ethernet, USB) fed by the supply.

Compliance: Meets EMC limits (e.g., 30 dBµV/m at 30 MHz), avoiding redesigns.

Design Considerations

Core Choice: Mn-Zn ferrite for kHz-MHz range; bigger cores for high power (e.g., 1 kW inverters).

Inductance: 1-20 mH for power apps—enough to choke 10 kHz-10 MHz without overkill.

Current Rating: Match to max DM current (e.g., 5 A for a 60 W PSU) to avoid saturation.

Check: B=μNI/l<BsatB = mu N I / l < B_{ ext{sat}}B=μNI/l<Bsat (e.g., 0.4 T for ferrite).

Capacitors: Add Y-caps (nF range) post-choke to shunt residual CM to ground, but watch leakage current limits.

Size/Cost: A $2 toroid often beats a $20 filter network—keep it simple unless broadband noise demands more.

Real-World Nuances

SMPS: A 1 mH CMC cuts 1 MHz noise by 20 dB, but parasitics limit it above 50 MHz—pair with beads for RF.

Automotive: 100 µH chokes handle 40 V transients and 10 A, keeping ECUs noise-free.

Cheap Fixes: Clip-on ferrites on PSU cables work for quick EMI patches—don’t scoff at simplicity.

The industry might push complex EMI filters, but a single CMC often does 80% of the job—over-engineering’s a trap unless you’re chasing dB for certification.

Email us

Warning: Undefined variable $pronamepx in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php on line 67

Fatal error: Uncaught TypeError: count(): Argument #1 ($value) must be of type Countable|array, null given in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php:67 Stack trace: #0 D:\wwwroot\www.resistorsupplies.com\ziliao.php(146): include() #1 {main} thrown in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php on line 67