High Current Inductors: Innovations and Trends in Power Conversion

High current inductors are at the heart of power conversion, and recent innovations and trends are pushing them to handle more current (10 A to 500 A+), higher frequencies (up to 5 MHz), and tighter spaces—all while chasing efficiency and cost targets. Driven by EVs, renewables, 5G, and high-power computing, these advancements are reshaping how inductors perform in modern switch-mode power supplies (SMPS), inverters, and chargers. Let’s dive into what’s new, what’s trending, and what’s actually moving the needle.

Key Innovations

Next-Gen Core Materials

100 A inductors shrink 20-30% with 99% efficiency at 1 MHz vs. 97% for ferrite.

Example: A 50 µH, 150 A nanocrystalline inductor in an EV charger cuts core loss by 50%.

Nanocrystalline/Amorphous Alloys: Ultra-high saturation (1.5-2 T) and low loss, outpacing MPP (1.2 T).

High-Flux Composites: Blend powdered iron with polymers for 1-1.5 T and 1-5 MHz capability.

Soft Magnetic Composites (SMC): Insulated iron particles for 3D flux and high-frequency stability.

What:

Impact:

Trend: Shift from ferrite (0.4 T) to alloys for high-current, high-freq apps.

Advanced Winding Techniques

50 A inductor drops from 10 W to 2 W loss, critical for 400 V GaN PSUs.

Example: Multi-layer 100 A inductor in a solar inverter hits 99.5% efficiency.

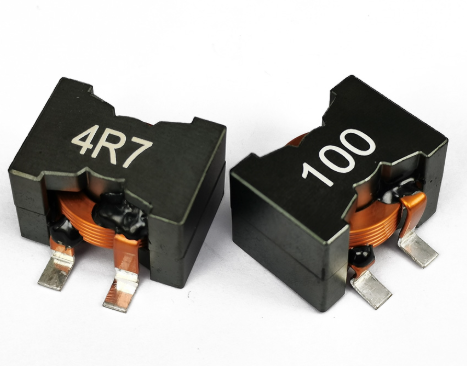

Multi-Layer Flat Wire: Stacked flat copper layers slash DCR (e.g., 1 mΩ vs. 5 mΩ) and boost density.

Litz Wire Evolution: Finer strands with optimized insulation for 1-5 MHz AC loss reduction.

Embedded Windings: Coils molded into cores or PCBs for planar designs.

What:

Impact:

Trend: Flat wire dominating high-current; Litz for MHz-range SMPS.

Planar and Coupled Inductor Designs

20 A, 10 µH planar fits 10x10 mm—50% smaller than toroids.

Coupled 100 A inductor in a 48 V server PSU cuts footprint by 40%, improves transient response.

Planar: PCB-integrated coils with flat cores, stacking for LLL.

Coupled: Multi-phase inductors sharing a core for multi-rail PSUs.

What:

Impact:

Trend: Planar for compact apps (5G, laptops); coupled for multi-phase (data centers, EVs).

Thermal Optimization

30 A at 1 MHz runs 25°C cooler, enabling denser EV or 5G designs.

Example: 200 A, 50 µH inductor in a 100 kW charger stays under 130°C with integrated cooling.

Direct-Cooled Cores: Metal slugs or liquid-cooled channels in inductors.

High-Temp Materials: 150-200°C ratings with advanced potting or insulation.

Open-Structure Designs: Maximize airflow in high-power setups.

What:

Impact:

Trend: Cooling tech scaling with power density—200°C parts on the horizon.

High-Frequency Compatibility

10 µH, 50 A inductor at 2 MHz cuts ripple caps by 50% in a GaN PSU.

Example: 47 µH, 30 A in a 5G base station hits 99% efficiency vs. 96% at 500 kHz.

Low-loss cores (SMC, amorphous) and reduced parasitics (spaced windings, shielding).

Tailored for SiC/GaN switching at 1-5 MHz.

What:

Impact:

Trend: MHz-range inductors exploding with wide-bandgap adoption.

Smart Manufacturing

Cuts tolerances (e.g., ±5% vs. ±20%), boosts reliability at 100 A.

Example: 3D-printed 50 A core in a prototype PSU fits odd spaces perfectly.

Automated winding for precision (flat wire, planar).

3D printing of cores or housings for custom shapes.

What:

Impact:

Trend: Niche but growing—cost still limits mass use.

Trends Shaping the Field

Efficiency Push

Driver: Green regs (e.g., EU Eco-Design) and cost savings at scale.

Shift: 1-2% gains (97% → 99%) via low DCR, low-loss cores—huge at 100 kW.

Example: 150 A EV inductor with 1 mΩ saves 20 W over 5 mΩ.

Miniaturization

Driver: EVs, 5G, portable power needing high density.

Shift: Planar and coupled designs cut size 30-50%; high-flux cores pack more LLL.

Example: 20 A, 22 µH SMD replaces a 20 mm toroid in a laptop PSU.

High-Frequency Adoption

Driver: SiC/GaN enabling 1-5 MHz switching—smaller passives, faster response.

Shift: Inductors with SRF >10 MHz, low loss at MHz—ferrite fading, alloys rising.

Example: 10 µH, 60 A at 2 MHz in a GaN charger shrinks total BOM.

Cost vs. Performance Balance

Driver: Mass-market (e.g., solar, consumer) vs. premium (EVs, aerospace).

Shift: Powdered iron holds for 20-50 A, <500 kHz; alloys for high-end 100 A+.

Example: $5 ferrite vs. $15 MPP—choice depends on margins.

Sustainability

Driver: Eco-focus on materials and lifespan.

Shift: Recyclable cores, lead-free windings, longer-life designs (150°C+).

Example: 80 A, 200 µH solar inductor with 20-year rating.

Impact on Power Conversion

EVs: 100-500 A inductors at 1 MHz enable 100 kW chargers in half the size—range and charge speed win.

Renewables: 50-200 A at 100 kHz with 99% efficiency cuts grid losses—MW-scale matters.

Data Centers: 20-100 A planar inductors at 2 MHz pack 48 V PSUs into 1U—density is king.

5G: 10-50 A at 1-5 MHz with low EMI powers compact base stations—RF can’t complain.

Reality Check

The buzz around “revolutionary” nano-cores or 3D-printed inductors sounds sexy, but flat-wire alloys and coupled designs are the real MVPs—delivering 90% of gains now. Ferrite and powdered iron aren’t dead—cheap and reliable for 20-50 A at <500 kHz. The bleeding edge (e.g., 200°C GaN inductors) is niche—cost keeps it there.

Email us

Warning: Undefined variable $pronamepx in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php on line 67

Fatal error: Uncaught TypeError: count(): Argument #1 ($value) must be of type Countable|array, null given in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php:67 Stack trace: #0 D:\wwwroot\www.resistorsupplies.com\ziliao.php(146): include() #1 {main} thrown in D:\wwwroot\www.resistorsupplies.com\moban\en_inc\ziliao.php on line 67