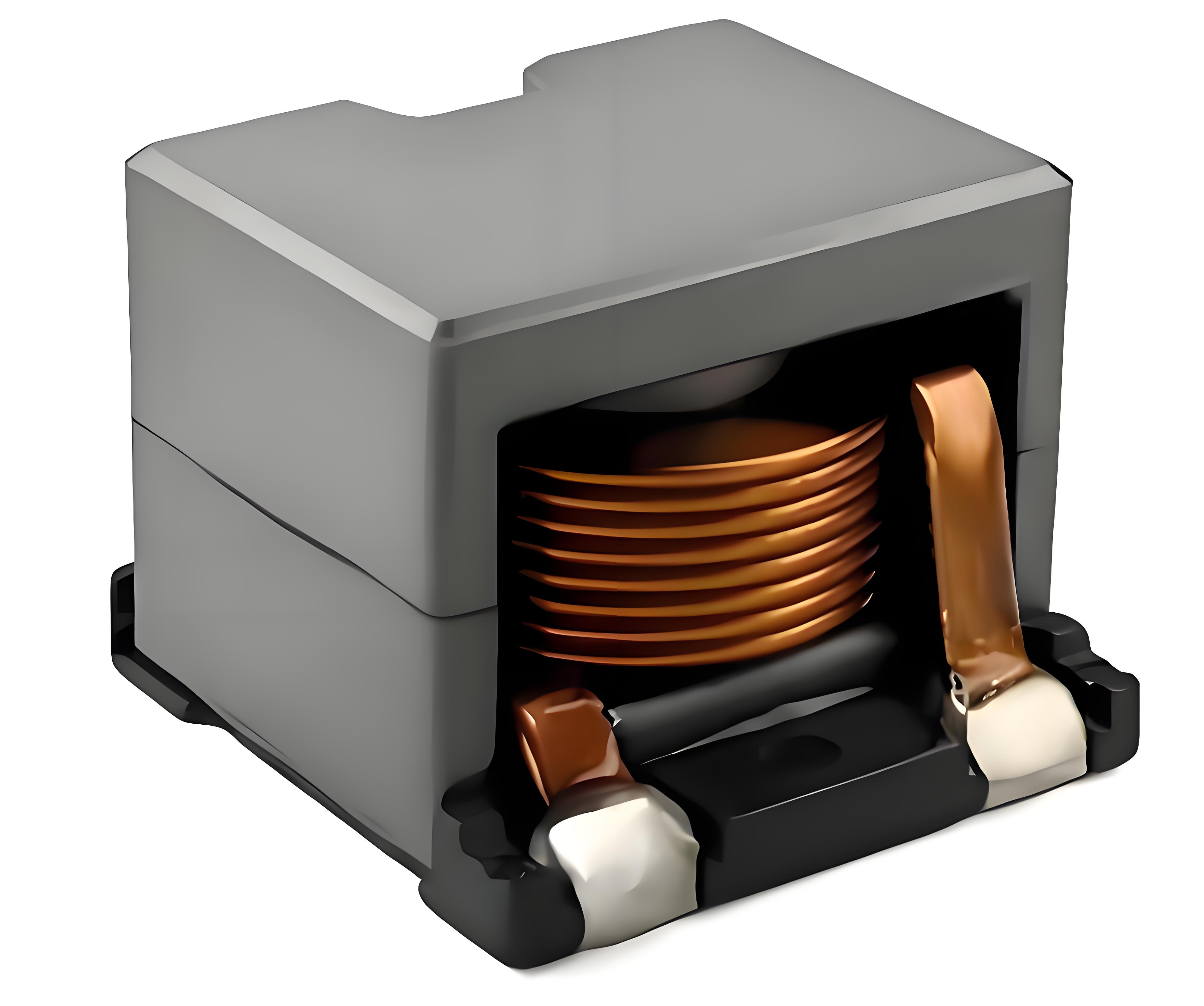

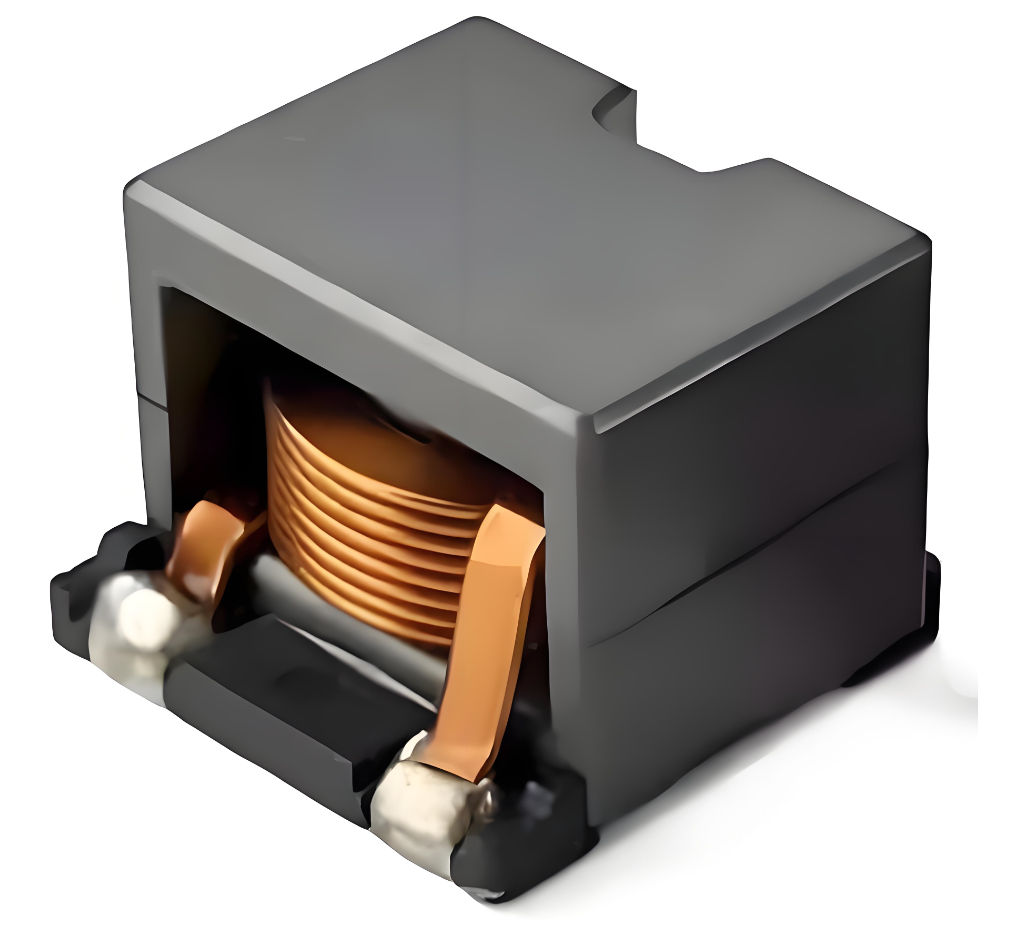

SMD Flat Wire Inductors: Key Advantages in Modern Electronics Manufacturing

Surface - mount device (SMD) flat wire inductors have become increasingly popular in modern electronics manufacturing. As electronic devices continue to shrink in size while demanding higher performance, SMD flat wire inductors offer unique advantages that address these challenges. This article explores the key benefits of SMD flat wire inductors and how they contribute to the advancement of electronic manufacturing.

Table of Contents

Introduction

In today's fast - paced world of electronics, the demand for miniaturization and high - performance components is relentless. Surface - mount technology (SMT) has revolutionized the way electronic components are manufactured and assembled. SMD flat wire inductors are a prime example of how innovation in component design can meet the evolving needs of the electronics industry. These inductors combine the benefits of surface - mount packaging with the superior electrical and thermal properties of flat wire construction.

Advantages of SMD Flat Wire Inductors

SMD flat wire inductors provide several key advantages that make them ideal for modern electronics manufacturing:

1. Size and Space Efficiency

SMD flat wire inductors are significantly smaller than traditional through - hole inductors. Their compact size allows for higher circuit density on printed circuit boards (PCBs), which is crucial for designing smaller electronic devices. The flat profile also enables better utilization of board space, as they can be placed closer to other components without interference.

2. Improved Electrical Performance

Flat wire construction results in lower AC resistance and reduced parasitic capacitance compared to round wire inductors. This leads to higher efficiency and better performance in high - frequency applications. The lower resistance translates to less power loss, while the reduced parasitic capacitance minimizes unwanted resonances and signal distortions.

3. Enhanced Thermal Management

The larger surface - to - volume ratio of flat wire inductors facilitates more efficient heat dissipation. This is particularly important in power - dense applications where heat generation can be a significant concern. Better thermal management not only improves the reliability of the inductor but also allows it to handle higher current levels without overheating.

4. Compatibility with Automated Assembly

As SMD components, flat wire inductors are compatible with automated surface - mount assembly processes. This compatibility leads to faster production times, lower manufacturing costs, and higher - yield assembly lines. The standardized packaging of SMD inductors also reduces the risk of placement errors during manufacturing.

5. Reliability and Durability

SMD flat wire inductors are designed to withstand the mechanical stresses encountered during manufacturing and operation. They are less prone to damage from soldering processes and have a more robust construction compared to some other types of inductors. This reliability is essential in applications where failure could lead to costly repairs or product recalls.

Data - Backed Advantages

The following table compares key performance metrics of SMD flat wire inductors with traditional through - hole inductors:

| Parameter | SMD Flat Wire Inductor | Traditional Through - Hole Inductor |

|---|---|---|

| Size ( typical dimensions ) | 2 - 5 mm × 1.2 - 3 mm × 1 - 2.5 mm | 4 - 10 mm × 3 - 8 mm × 3 - 7 mm |

| Inductance Range | 0.1 µH - 100 mH | 0.1 µH - 100 mH |

| Rated Current ( typical range ) | 0.1 A - 10 A | 0.05 A - 5 A |

| AC Resistance at 1 MHz ( typical ) | 0.05 - 1 ohm | 0.1 - 2 ohms |

| Parasitic Capacitance ( typical ) | 0.3 - 1.5 pF | 0.5 - 2.5 pF |

| Thermal Resistance ( typical ) | 15 - 30 °C/W | 25 - 50 °C/W |

This data clearly demonstrates the superiority of SMD flat wire inductors in terms of size, electrical performance, and thermal management.

Comparison with Traditional Inductors

While traditional through - hole inductors have been widely used for many years, SMD flat wire inductors offer distinct advantages in modern electronics manufacturing. Traditional inductors often require more board space, have higher profile heights, and are less compatible with automated assembly processes. They also typically exhibit higher AC resistance and parasitic capacitance, which can limit their performance in high - frequency and high - power applications.

However, traditional inductors may still be suitable for certain low - frequency or high - power applications where size and automation compatibility are less critical. The choice between SMD flat wire inductors and traditional inductors should be based on the specific requirements of the application, including factors like frequency range, power levels, size constraints, and manufacturing considerations.

Applications in Modern Electronics

SMD flat wire inductors are finding their way into a wide range of modern electronic applications due to their advantages:

1. Mobile Devices

In smartphones, tablets, and other portable devices, SMD flat wire inductors enable the integration of more functionality into smaller form factors. Their compact size and high - performance characteristics are essential for power management circuits, RF modules, and other critical subsystems within these devices.

2. Wearable Technology

Wearable devices such as smartwatches and fitness trackers require extremely compact components. SMD flat wire inductors meet these space constraints while providing reliable performance for functions like wireless communication and power regulation.

3. Automotive Electronics

In the automotive industry, SMD flat wire inductors are used in various electronic control units (ECUs), infotainment systems, and advanced driver - assistance systems (ADAS). Their reliability and ability to handle the harsh environmental conditions found in vehicles make them an ideal choice.

4. Industrial Automation

For industrial applications, SMD flat wire inductors are employed in power supplies, motor control circuits, and sensor interfaces. Their robust construction and efficient thermal management ensure stable operation in demanding industrial environments.

5. IoT Devices

Internet - of - Things (IoT) devices, which often have strict size and power requirements, benefit from the space - saving and high - efficiency features of SMD flat wire inductors. These inductors are used in the power management and communication modules of IoT sensors and actuators.

Problem and Solution

Despite their advantages, SMD flat wire inductors can present challenges in certain applications. One common issue is the potential for higher manufacturing costs compared to traditional through - hole inductors. The specialized manufacturing processes required for producing flat wire inductors and their compatibility with SMD assembly equipment can lead to increased expenses.

Solution: To address this problem, manufacturers are continuously optimizing their production techniques to reduce costs. Additionally, the long - term benefits of using SMD flat wire inductors, such as improved reliability, higher performance, and space - saving capabilities, often outweigh the initial cost considerations. For high - volume production runs, the cost - effectiveness of SMD flat wire inductors becomes more apparent due to their compatibility with automated assembly lines and reduced assembly time. Furthermore, selecting inductors from reputable manufacturers who offer competitive pricing and quality assurance can help mitigate cost concerns.

Conclusion

SMD flat wire inductors represent a significant advancement in electronic component technology, offering numerous advantages that align with the trends of modern electronics manufacturing. Their compact size, superior electrical performance, enhanced thermal management, and compatibility with automated assembly processes make them an indispensable choice for a wide range of applications. While challenges such as manufacturing costs exist, the ongoing improvements in production techniques and the long - term benefits they provide continue to solidify the position of SMD flat wire inductors in the electronics industry. As electronic devices continue to evolve, SMD flat wire inductors will likely play an increasingly important role in enabling the next generation of innovative and high - performing products.