Unveiling the Hidden Advantages of Flat Wire Inductors in Modern Circuits

In the intricate realm of modern electronics, inductors play a crucial role in various applications ranging from power supplies to signal processing. Among the different types of inductors available, flat wire inductors have been gaining significant attention due to their unique advantages that can lead to more efficient circuit designs. This article aims to explore these hidden benefits and how they can be leveraged in contemporary electronic systems.

Table of Contents

Introduction

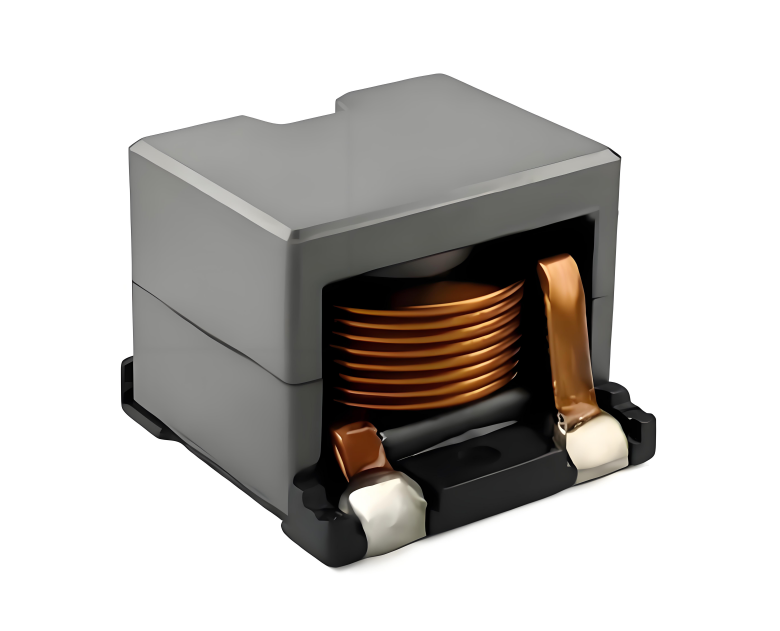

Inductors are fundamental passive components in electronic circuits, storing energy in a magnetic field when current flows through them. Flat wire inductors, as the name suggests, utilize flat wire instead of the conventional round wire. This seemingly small difference can have substantial implications for the performance and efficiency of electronic devices. As technology advances and demands for smaller, more powerful devices increase, understanding the advantages of flat wire inductors becomes increasingly important.

Advantages of Flat Wire Inductors

Flat wire inductors offer several distinct advantages that make them a superior choice in many modern circuit applications. Let's delve into these benefits:

1. Higher Current Handling Capacity

Flat wire inductors can handle higher currents compared to their round wire counterparts. The flat shape of the wire provides a larger surface area, allowing for better dissipation of heat generated during operation. This results in the ability to carry higher currents without excessive temperature rise, which is crucial in power electronics applications.

2. Reduced AC Resistance

Due to their geometry, flat wire inductors exhibit lower AC resistance. The skin effect, which causes current to concentrate near the surface of a conductor at high frequencies, is mitigated in flat wires. This leads to lower resistive losses and improved efficiency, especially in high - frequency circuits.

3. Compact Size and Space Efficiency

Flat wire inductors can be designed to occupy less space while maintaining or even improving performance. The flat profile allows for more efficient use of board space, which is highly valuable in today's compact electronic devices. This space - saving characteristic enables the integration of more components into smaller form factors.

4. Improved Thermal Management

The larger surface - to - volume ratio of flat wire inductors facilitates better heat transfer. This enhanced thermal management capability ensures that the inductor operates within safe temperature limits, prolonging its lifespan and reliability. In applications where thermal performance is critical, such as in high - power converters, this advantage is particularly significant.

5. Lower Parasitic Capacitance

Flat wire inductors typically have lower parasitic capacitance compared to round wire inductors. Parasitic capacitance can lead to unwanted resonances and signal distortions in high - frequency circuits. By reducing this capacitance, flat wire inductors contribute to more stable and predictable circuit behavior.

Data - Backed Comparison

To illustrate the advantages of flat wire inductors more concretely, consider the following data comparing flat wire inductors with traditional round wire inductors:

| Parameter | Flat Wire Inductor | Round Wire Inductor |

|---|---|---|

| Current Handling Capacity (Typical Range) | 10 - 100 A | 5 - 50 A |

| AC Resistance at 1 MHz (Typical Value) | 0.01 - 0.1 ohm | 0.02 - 0.2 ohm |

| Size Reduction (Typical Percentage) | 20 - 40% | - |

| Thermal Resistance (Typical Value) | 10 - 20°C/W | 15 - 30°C/W |

| Parasitic Capacitance (Typical Range) | 0.5 - 2 pF | 1 - 3 pF |

These data points highlight the superior performance of flat wire inductors across multiple critical parameters.

Comparison with Traditional Inductors

While traditional round wire inductors have been widely used and have their own set of advantages, such as lower cost and simpler manufacturing processes in some cases, flat wire inductors offer a range of benefits that can outweigh these factors in many modern applications. The table above provides a clear comparison, but it's important to note that the choice between flat wire and round wire inductors should be based on the specific requirements of the application, including factors like frequency range, power levels, size constraints, and thermal considerations.

Applications in Modern Circuits

The advantages of flat wire inductors make them well - suited for a variety of modern circuit applications:

1. Power Converters

In high - efficiency power converters, such as those used in renewable energy systems and electric vehicles, flat wire inductors help minimize losses and improve power density. Their ability to handle high currents and dissipate heat effectively is crucial in these high - power applications.

2. RF and Microwave Circuits

For radio frequency and microwave applications, the low AC resistance and reduced parasitic capacitance of flat wire inductors lead to better performance in terms of signal integrity and bandwidth. This makes them ideal for use in communication devices and wireless systems.

3. Automotive Electronics

The compact size and robust thermal performance of flat wire inductors are highly beneficial in the harsh environment of automotive electronics. They can be used in various systems within vehicles, from infotainment to advanced driver - assistance systems (ADAS).

4. Consumer Electronics

In devices like smartphones, laptops, and tablets, where space is at a premium, flat wire inductors enable the integration of more functionality without increasing the form factor. This aligns with the trend of creating smaller, more powerful consumer electronic products.

Problem and Solution

While flat wire inductors offer numerous advantages, there are challenges associated with their implementation. One common problem is the potential for increased manufacturing complexity compared to traditional round wire inductors. The flat wire geometry may require specialized winding techniques and equipment, which can lead to higher production costs and technical hurdles.

Solution: To address this issue, manufacturers are developing advanced winding machines and processes specifically designed for flat wire inductors. These innovations help reduce production costs and improve manufacturing yields. Additionally, the long - term benefits of using flat wire inductors, such as improved efficiency and reliability, often justify the initial investment in specialized manufacturing equipment. Collaboration between inductor manufacturers and circuit designers can also lead to optimized designs that balance performance requirements with manufacturing feasibility.

Conclusion

Flat wire inductors present a range of hidden advantages that can significantly enhance the performance of modern electronic circuits. From higher current handling and reduced AC resistance to compact size and improved thermal management, these inductors offer compelling benefits for a variety of applications. While there are challenges in their manufacturing and implementation, the solutions being developed continue to make flat wire inductors a viable and advantageous choice in the evolving landscape of electronics. As technology progresses and the demand for efficient, compact, and high - performance electronic devices grows, flat wire inductors are likely to play an increasingly important role in meeting these requirements.