High - Performance Shielded Inductors for Industrial Control Boards: Ensuring Reliability in Critical Applications

In industrial control systems, reliability and efficiency are paramount. High - performance shielded inductors play a crucial role in achieving these objectives by providing stable power delivery and minimizing electromagnetic interference (EMI). This article explores the design, performance characteristics, and applications of shielded inductors in industrial control boards, offering insights into their importance and practical considerations for engineers.

Table of Contents

Introduction

Shielded inductors are essential components in industrial control boards, where they help regulate power, filter noise, and ensure stable operation of control systems. Their ability to contain magnetic fields and reduce EMI makes them indispensable in the harsh electromagnetic environments typical of industrial settings.

Design and Construction of Shielded Inductors

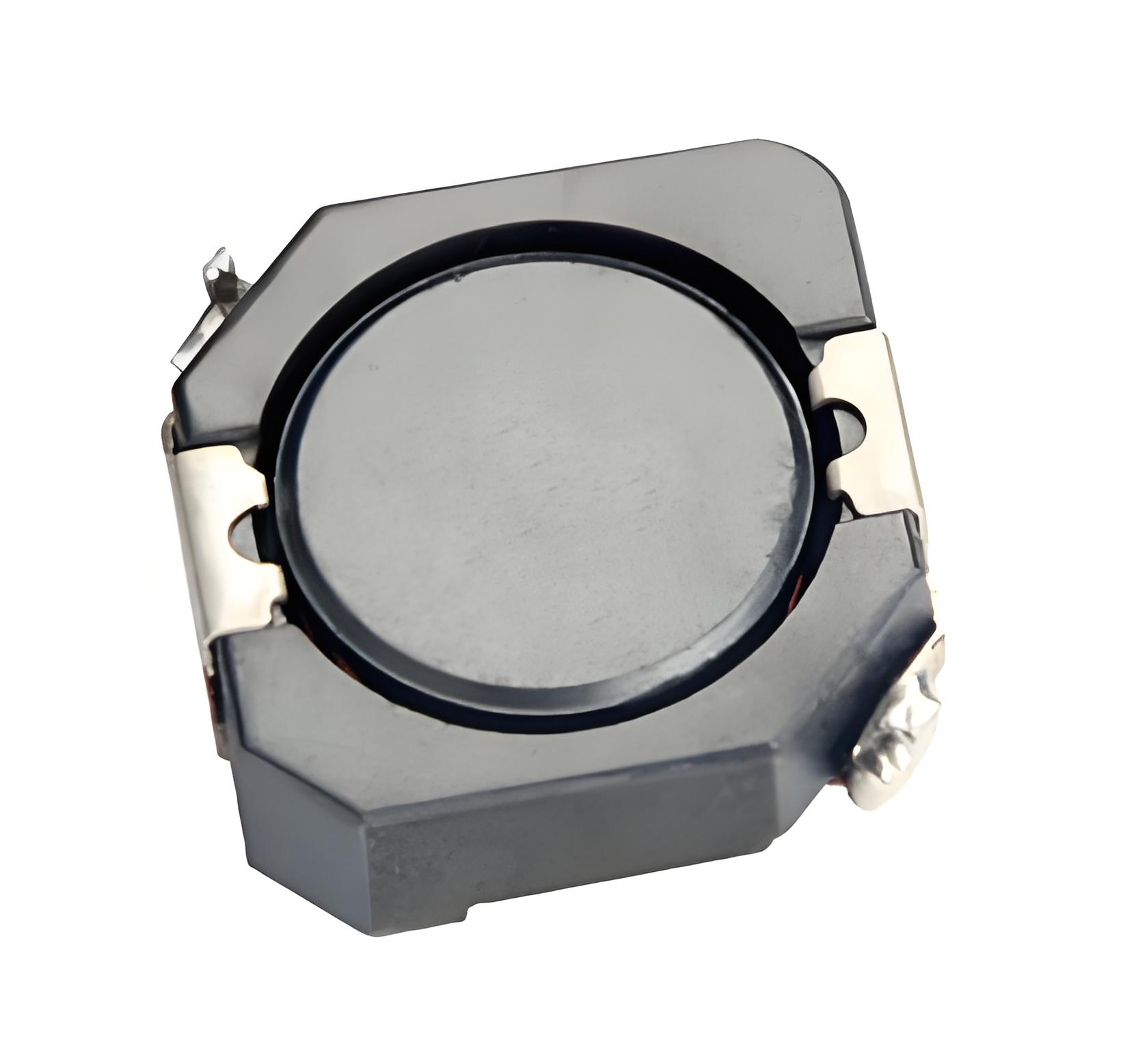

Shielded inductors are designed to optimize performance in industrial applications. The core is typically made of ferrite or powdered iron materials, which provide high permeability and low core losses. The wire used for the winding is usually copper, offering low resistance to minimize power losses.

Shielding

The shielding in these inductors is achieved by enclosing the winding in a magnetic shield, typically made of ferrite material. This shield helps to contain the magnetic field within the inductor, reducing EMI and improving the overall efficiency of the circuit.

Structure

Shielded inductors have a compact, flat structure that allows for efficient use of board space. The inductor is mounted directly onto the PCB (Printed Circuit Board), with terminals for electrical connections.

Performance Characteristics

Shielded inductors offer several key performance characteristics that make them suitable for industrial control applications.

| Parameter | Shielded Inductor |

|---|---|

| Inductance Range | 0.1 µH - 100 µH |

| Current Rating | 0.1 A - 20 A |

| Shielding Effectiveness | Reduces EMI by 80% - 95% |

| Operating Temperature Range | -40°C to +125°C |

| DC Resistance | 0.01 Ω - 1 Ω |

| Size | Compact, typically 5 - 15 mm in length |

Applications in Industrial Control Boards

Shielded inductors are used in various applications within industrial control systems.

Power Supplies

In power supply circuits, shielded inductors help regulate voltage and current, ensuring stable power delivery to microcontrollers, sensors, and actuators.

Motor Drivers

Shielded inductors are used in motor driver circuits to filter noise and provide smooth power delivery to motors, improving control accuracy and reducing vibration.

Filter Circuits

Shielded inductors are used in EMI filter circuits to reduce electrical noise and protect sensitive components from interference.

Problem and Solution

A common problem in industrial control systems is the interference caused by electromagnetic noise, which can lead to system malfunctions and reduced reliability.

Solution: The use of shielded inductors effectively addresses this issue by containing the magnetic field and reducing EMI. Proper placement of shielded inductors in the circuit design, along with the use of ground planes and shielding techniques, can significantly improve the electromagnetic compatibility of the system.

Best Practices for Using Shielded Inductors

Proper Soldering Techniques: Use proper soldering techniques to ensure reliable connections and avoid thermal stress on the inductor.

Thermal Management: Implement effective heat dissipation solutions to prevent overheating, especially in high - power applications.

EMI Considerations: Place shielded inductors away from sensitive components and use ground planes to further reduce EMI.

Current Limiting: Ensure that the inductor is operated within its specified current rating to prevent saturation and damage.

Conclusion

Shielded inductors are vital components in industrial control boards, offering reliable performance and effective EMI reduction. Their design and performance characteristics make them suitable for a wide range of applications in industrial control systems. By following best practices in their selection and use, engineers can enhance the reliability and efficiency of industrial control systems.