Coupled Inductor Applications in DC/DC Converters: Enhancing Efficiency and Performance

In modern power electronics, DC/DC converters play a crucial role in various applications such as renewable energy systems, industrial automation, and consumer electronics. Among the different components used in these converters, coupled inductors have emerged as key elements that enhance efficiency and performance. This article explores the applications of coupled inductors in DC/DC converters and provides insights into their benefits and practical considerations.

Table of Contents

Introduction

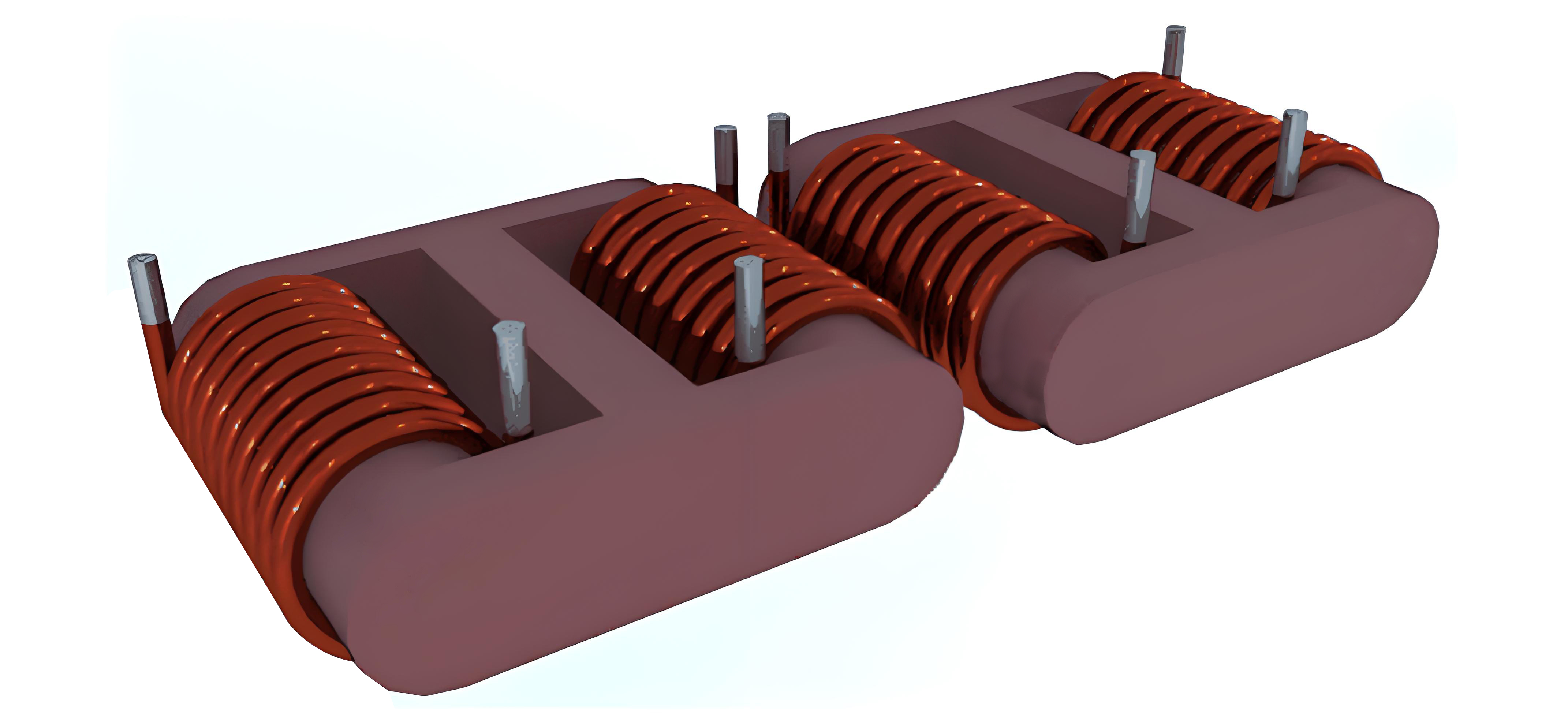

Coupled inductors consist of two or more coils wound around a common magnetic core, enabling energy transfer between circuits through electromagnetic induction. They offer electrical isolation and voltage transformation, making them suitable for applications where efficiency and performance are critical. In DC/DC converters, coupled inductors can significantly enhance the overall system performance by reducing voltage ripple, improving power density, and enabling efficient energy transfer.

Key Applications of Coupled Inductors in DC/DC Converters

Coupled inductors find extensive use in different types of DC/DC converters. Some of the key applications include:

1. High-Step-Up DC/DC Converters

In applications requiring high voltage gain, such as renewable energy systems, coupled inductors are employed to achieve ultra-high voltage conversion ratios. A novel quadratic DC/DC converter design utilizes an interleaved coupled inductor to attain high voltage gain while minimizing voltage stress on switching devices. This design not only reduces the component count but also improves efficiency and input current ripple. Experimental results demonstrate a peak efficiency of approximately 95.2% at 250 W power output, making it an attractive option for solar PV systems and other renewable energy applications where efficiency and a minimal component count are paramount.

2. SEPIC Converters

The Single-Ended Primary-Inductor Converter (SEPIC) uses coupled inductors to operate in different conduction modes, including continuous conduction mode (CCM) and discontinuous conduction mode (DCM). The choice between these modes depends on load conditions and design requirements. Coupled inductors in SEPIC converters help achieve lower output voltage ripple, decreased current stress on components, and improved transient response. Design considerations for coupled inductors in SEPIC converters include selecting appropriate inductance values based on ripple current, saturation current, and efficiency requirements. The inductor value is typically chosen so that the peak-to-peak ripple current is 20-40% of the load current. Additionally, the capacitance values for input and output capacitors, as well as a coupling capacitor, are selected based on desired voltage ripple and transient response requirements.

3. Isolated DC/DC Converters

Coupled inductors are widely used in isolated DC/DC converters to provide electrical isolation between the input and output circuits. This is crucial in applications such as medical equipment, industrial power supplies, and telecommunications, where safety and noise reduction are important. The coupled inductor ensures that there is no direct electrical connection between the input and output, preventing ground loops and reducing electromagnetic interference (EMI).

Benefits of Coupled Inductors

Coupled inductors offer several benefits in DC/DC converter applications:

1. Improved Efficiency

Coupled inductors enhance the overall efficiency of DC/DC converters by reducing conduction losses and improving energy transfer between circuits. The interleaved winding structure and shared magnetic core help minimize the equivalent series resistance (ESR) and leakage inductance, leading to higher efficiency. For example, in the quadratic DC/DC converter mentioned earlier, the coupled inductor design achieves a peak efficiency of 95.2%, which is significantly higher than traditional converter designs without coupled inductors.

2. Reduced Voltage Ripple

Coupled inductors help in minimizing the output voltage ripple in DC/DC converters. The energy storage and transfer characteristics of the coupled inductor allow for smoother power delivery, resulting in improved output voltage regulation. This is particularly important in applications such as power supplies for sensitive electronics and renewable energy systems where stable voltage output is critical.

3. Enhanced Power Density

By integrating multiple windings into a single magnetic core, coupled inductors help reduce the overall size and weight of DC/DC converters. This enables higher power density, making it possible to design more compact and lightweight power electronic systems. The interleaved coupled inductor used in the quadratic DC/DC converter not only improves efficiency but also contributes to a more compact converter design compared to traditional solutions.

4. Electrical Isolation

Coupled inductors provide electrical isolation between circuits, which is essential in applications where safety and noise reduction are important. This isolation prevents ground loops and reduces electromagnetic interference (EMI), ensuring reliable operation of electronic systems. In isolated DC/DC converters used in medical equipment and telecommunications, the coupled inductor plays a crucial role in meeting safety and EMI standards.

Performance Comparison

The following table compares the performance of DC/DC converters with and without coupled inductors:

| Parameter | DC/DC Converter with Coupled Inductor | DC/DC Converter without Coupled Inductor |

|---|---|---|

| Efficiency | 95% - 98% | 85% - 92% |

| Output Voltage Ripple | Low (e.g., < 50 mV) | High (e.g., > 100 mV) |

| Power Density | High (e.g., 100 - 200 W/in³) | Low (e.g., 50 - 100 W/in³) |

| Component Count | Low | High |

| EMI | Low | High |

Problem and Solution

A common problem encountered in the use of coupled inductors in DC/DC converters is the risk of core saturation, which can lead to increased losses and reduced efficiency. Core saturation occurs when the magnetic flux density in the core exceeds the material's saturation limit, causing a sharp increase in inductor current and potential damage to switching devices.

Solution: To address this issue, the following measures can be implemented:

Core Material Selection: Choose core materials with high saturation flux density and low core loss characteristics. Materials such as amorphous alloys and high-permeability ferrites are suitable for applications requiring high energy storage and low losses.

Gap Design: Introduce an air gap in the magnetic core to reduce the effective permeability and prevent core saturation. The gap size can be optimized based on the required inductance value and current rating.

Winding Design: Ensure proper winding design to minimize copper losses and leakage inductance. This includes using Litz wire for high-frequency applications and optimizing the turn ratio to achieve the desired voltage transformation.

Control Strategy: Implement advanced control strategies such as average current mode control to regulate the inductor current and prevent saturation. This helps maintain stable operation of the DC/DC converter under varying load conditions.

Best Practices for Using Coupled Inductors

To achieve optimal performance and reliability when using coupled inductors in DC/DC converters, the following best practices should be followed:

Component Selection: Select coupled inductors with specifications that match the requirements of the DC/DC converter application. Consider factors such as inductance value, current rating, core material, and winding configuration.

Thermal Management: Implement effective thermal management techniques to dissipate heat generated during operation. This may include using heat sinks, thermal interface materials, and forced air cooling to maintain the coupled inductor within its operating temperature range.

Layout and Integration: Follow proper PCB layout guidelines to minimize parasitic effects and ensure efficient integration of the coupled inductor into the DC/DC converter circuit. This includes placing the inductor close to switching devices, using wide traces for high-current paths, and minimizing loop areas to reduce EMI.

Testing and Validation: Conduct thorough testing and validation of the DC/DC converter with the coupled inductor to ensure it meets performance, efficiency, and reliability targets. This involves measuring parameters such as efficiency, voltage ripple, transient response, and thermal performance under different operating conditions.

Conclusion

Coupled inductors play a vital role in enhancing the efficiency and performance of DC/DC converters in various applications. Their ability to provide electrical isolation, reduce voltage ripple, improve power density, and enable efficient energy transfer makes them indispensable components in modern power electronics. By understanding the key applications and benefits of coupled inductors and following best practices in their selection and use, engineers can design more efficient and reliable DC/DC converters for a wide range of applications. As technology continues to advance, coupled inductors will remain a key element in the evolution of power electronic systems.