Introduction

In modern power electronics, the quest for higher efficiency and power density has driven innovation in component design. Planar inductor design stands out as a crucial advancement that addresses the limitations of traditional inductors. By integrating planar technology into power converters, engineers can achieve remarkable improvements in efficiency, size reduction, and thermal management. This article explores the principles of planar inductor design, its benefits for power converters, and practical solutions to common design challenges.

Table of Contents

Planar Inductor Basics

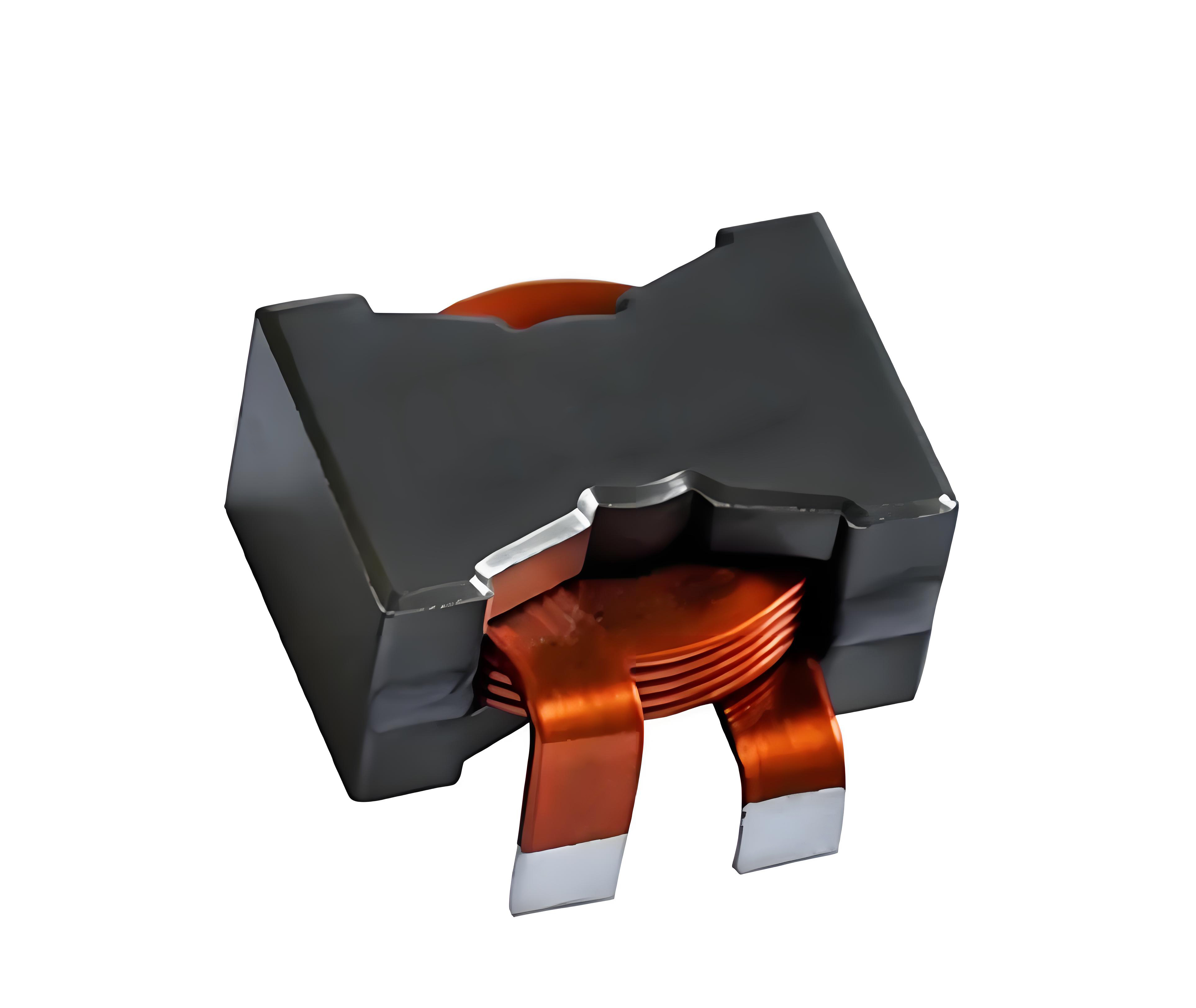

Planar inductors differ significantly from traditional wire - wound inductors. They utilize printed circuit board (PCB) technology or specialized materials to create a flat, low - profile inductor. The design typically consists of:

Coplanar conductive patterns for the winding

A magnetic core material (ferrite, powdered iron, or composite materials)

Insulation layers to prevent short circuits

These inductors are characterized by their compact size, reduced height, and excellent high - frequency performance. Their planar structure allows for better integration with other power converter components.

Benefits for Power Converters

Planar inductors offer several advantages that make them ideal for power converter applications:

| Benefit | Description | Typical Improvement |

|---|---|---|

| Reduced AC Resistance | Lower resistive losses due to wide, flat conductors | 30 - 70% reduction in resistive losses |

| Lower Core Losses | Optimized magnetic materials for high - frequency operation | 20 - 50% reduction in core losses |

| Improved Thermal Management | Planar structure allows better heat dissipation | Temperature rise reduced by 15 - 30% |

| Smaller Footprint | Low - profile design saves board space | 40 - 60% reduction in volume |

| Better Parasitic Characteristics | Reduced parasitic capacitance and inductance | Parasitic elements reduced by 50 - 70% |

| Higher Power Density | Combination of size reduction and efficiency gains | Power density increased by 2 - 4x |

Common Challenges in Planar Inductor Design

While planar inductors offer numerous benefits, designers face several challenges:

Achieving sufficient inductance values in small footprints

Managing the trade - off between DC resistance and size

Ensuring adequate magnetic shielding to prevent interference

Addressing manufacturing complexities and costs

Maintaining performance across a wide temperature range

Optimizing the balance between core material and winding design

A common problem in high - power density applications is the difficulty in achieving low DC resistance while maintaining a compact size. For example, in a high - current DC - DC converter, the planar inductor may require very wide conductive traces, which can increase the footprint beyond acceptable limits.

Solutions to Enhance Efficiency

To address these challenges and maximize the efficiency of planar inductors in power converters:

Use laminated core structures to reduce eddy current losses

Implement multi - layer PCB techniques to increase effective conductor width

Select high - permeability core materials for better magnetic confinement

Optimize winding patterns to minimize parasitic elements

Employ thermal vias to improve heat dissipation from the core

Use copper - clad laminates to reduce resistive losses

In high - current applications, multi - layer PCB techniques can effectively reduce DC resistance without significantly increasing the footprint. For instance, using a 4 - layer PCB design with interleaved winding patterns can reduce DC resistance by 40 - 60% compared to a single - layer design, while only increasing the footprint by 10 - 15%.

Case Study: High - Efficiency DC - DC Converter

Consider a high - efficiency DCDC- converter designed for a telecom application. The performance of the converter depends heavily on the inductor design. Here's how planar inductor design can improve the converter's efficiency:

| Parameter | Traditional Wire - Wound Inductor | Planar Inductor Design |

|---|---|---|

| Conversion Efficiency | 88% | 93% |

| Power Density | 50W/in³ | 120W/in³ |

| Component Height | 12mm | 6mm |

| Thermal Resistance | 25°C/W | 15°C/W |

| Parasitic Inductance | 15nH | 5nH |

| Manufacturing Cost | $1.80 | $2.40 |

In this case study, replacing the traditional wire - wound inductor with a planar inductor design resulted in a 5% improvement in conversion efficiency and more than doubling the power density. The reduced height allowed for a more compact converter design, while the lower thermal resistance improved reliability by reducing component temperatures. Although the manufacturing cost increased, the overall system cost decreased due to the reduced size and improved efficiency.

Practical Design Tips

When designing planar inductors for power converters, consider the following practical tips:

Optimize the core geometry for your specific frequency range

Use simulation tools to model magnetic fields and optimize winding patterns

Consider the skin effect and proximity effect in high - frequency designs

Implement proper creepage and clearance distances for safety

Use thermal simulation to identify and mitigate hot spots

Balance cost and performance by selecting appropriate core materials

For example, when designing a planar inductor for a 500kHz DC - DC converter, use ferrite core materials with permeability optimized for this frequency range. Simulate the magnetic field distribution to ensure adequate magnetic confinement and minimize core losses. Implement thermal vias every 5 - 10mm² to efficiently transfer heat from the core to a heat sink.

Conclusion

Planar inductor design represents a significant advancement in power converter technology. By addressing the common challenges through thoughtful design and optimization, engineers can achieve remarkable improvements in efficiency, power density, and thermal performance. As demonstrated in our case study, planar inductors can transform the performance of power converters, making them essential for modern high - efficiency power electronics applications.