What Are Flat Top Air Core Inductors?

What Are Flat Top Air Core Inductors?

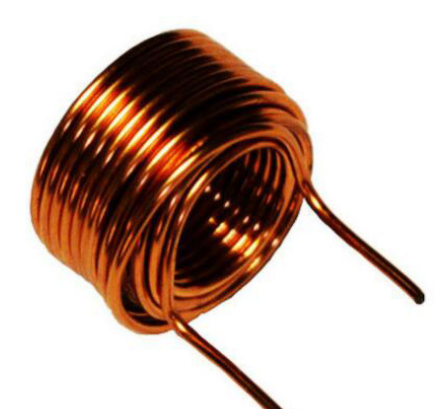

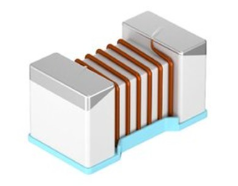

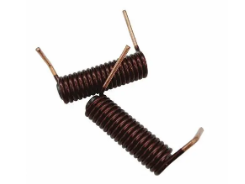

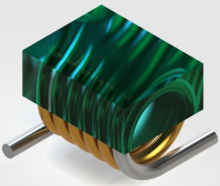

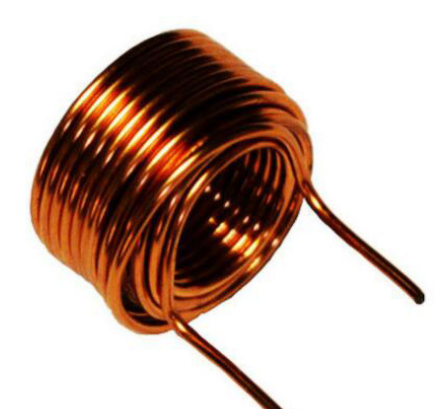

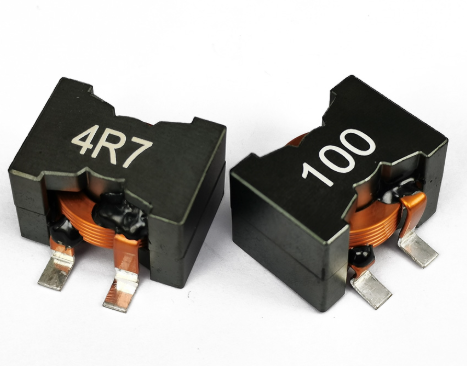

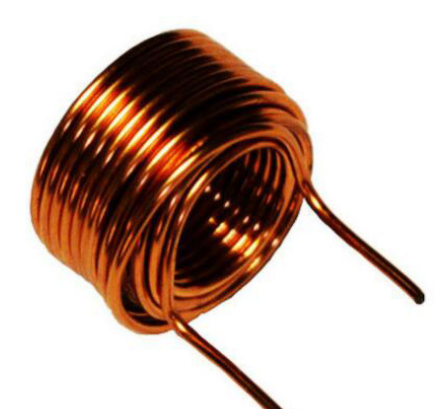

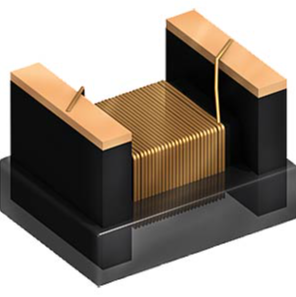

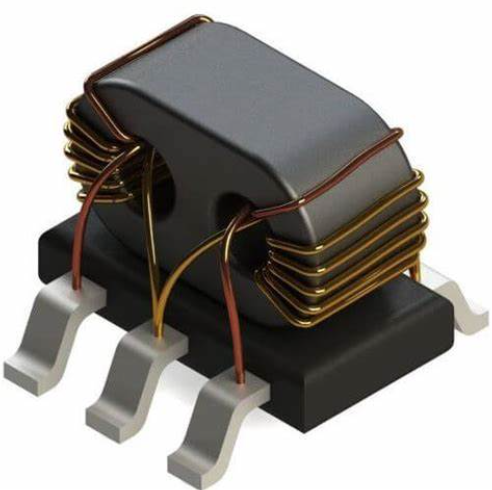

Flat top air core inductors are a subset of air core inductors—coils wound without a magnetic core (just air or a non-magnetic former), often with a flattened top surface for surface-mount (SMD) compatibility. Unlike ferrite or iron core inductors, they use air as the medium for magnetic flux, giving them unique properties:

High-Frequency Performance: No core saturation or hysteresis losses, ideal for RF and high-speed circuits.

Low Distortion: Excellent linearity, critical for signal integrity.

Compact Design: The "flat top" often implies a low-profile, SMD-friendly shape suited for modern electronics.

Competitive Strengths

To maintain market competitiveness, flat top air core inductors lean on these advantages:

Demand in High-Frequency Applications:

5G and Telecom: The rollout of 5G and IoT devices demands components that excel at GHz frequencies. Air core inductors shine here—ferrite cores start losing efficiency above 100 MHz due to core losses, while air cores handle up to 1 GHz or more.

RF Circuits: Used in radio transmitters, receivers, and antennas, where their low distortion keeps signals clean. Flat top designs fit snugly into compact RF modules.

Miniaturization Trend:

Electronics are shrinking—think smartphones, wearables, and EVs. The flat top SMD design aligns perfectly, offering a low profile (e.g., 0.8–2 mm height) and easy integration onto PCBs. Competitors like toroidal inductors are bulkier and less SMD-friendly.

Example: A flat top air core inductor (e.g., 5nH–50nH range) can fit into a 0402 or 0603 package, ideal for space-constrained designs.

Cost and Simplicity:

No magnetic core means fewer materials and simpler manufacturing than ferrite or metal alloy inductors. This keeps costs down, a big plus in price-sensitive markets like consumer electronics.

Companies like Coilcraft or Zhuhai Eastever (a Chinese supplier) mass-produce these, leveraging economies of scale.

Reliability in Harsh Conditions:

Without a core to saturate or degrade, they’re stable across wide temperature ranges (e.g., -40°C to +125°C). This makes them competitive in automotive (e.g., ADAS) or aerospace applications, where ferrite cores might falter.

Challenges to Competitiveness

They’re not invincible—here’s where they need to adapt:

Competition from Ferrite/Metal Core Inductors:

For power applications (e.g., DC-DC converters, EVs), air cores lose out. They have lower inductance per size (nH range vs. µH for ferrite), making them less suited for high-current tasks. Ferrite cores dominate where high inductance or power handling is key.

Flat top air cores must carve a niche in RF/signal-focused markets rather than broad power applications.

Innovation Pressure:

Rivals like TDK or Murata are pushing multilayer and metal composite inductors with tiny footprints and decent high-frequency performance. Flat top air cores need to keep evolving—say, with tighter tolerances (e.g., ±5% inductance) or higher Q-factors (quality factor for efficiency).

Raw Material Costs:

While simpler, copper wire prices fluctuate. Manufacturers must optimize winding techniques or explore alternatives (e.g., aluminum) to stay cost-competitive.

Strategies to Stay Competitive

Here’s how flat top air core inductors can hold their ground:

Target Growth Sectors:

EVs and Renewables: Focus on auxiliary RF circuits (e.g., wireless charging comms) rather than main power systems.

Consumer Electronics: Ride the wave of wearables and smart home devices needing compact, high-frequency components.

Enhance Design:

Push for higher Q-factors or self-resonant frequencies (SRF) to outpace multilayer rivals. For instance, a flat top air core with an SRF above 5 GHz could dominate RF niches.

Offer customization—e.g., Zhuhai Eastever’s catalog shows inductance from 2.5nH to 68nH, tweakable for specific needs.

Leverage Market Trends:

The inductor market’s growing (e.g., projected to hit $10.8B by 2032 per some reports). Flat top air cores can grab share in the RF segment (8.6% CAGR) by aligning with 5G/IoT demand.

Sustainability angle: Highlight their lack of rare-earth materials (unlike some ferrite cores) for eco-conscious buyers.

Critical Take

The establishment might overhype fancy multilayer or metal alloy inductors, but flat top air cores have a quiet, solid niche. They’re not flashy, but their simplicity and RF prowess keep them relevant. The real test is staying ahead of miniaturization and cost curves—stagnation could let ferrite-based SMDs steal their thunder. Data backs their use (e.g., Asia-Pacific’s electronics boom), but their competitiveness hinges on execution, not just inherent traits.

Email us

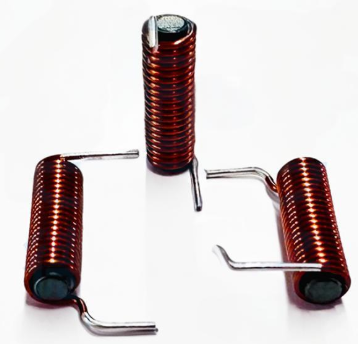

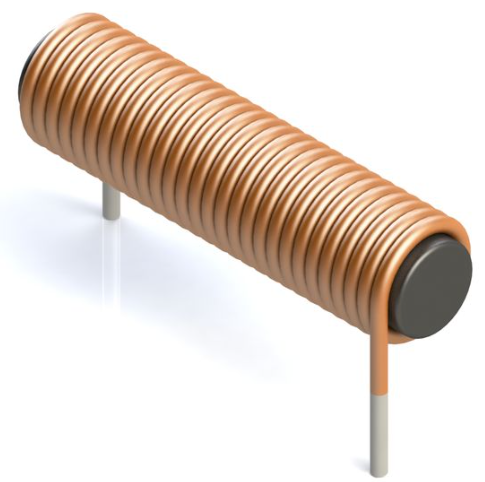

Ferrite Core Magnetic Rod Coil, High Current Through-Hole Magnetic Rod Coil, Iron Core

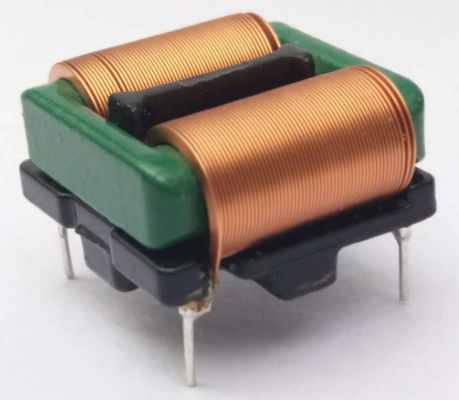

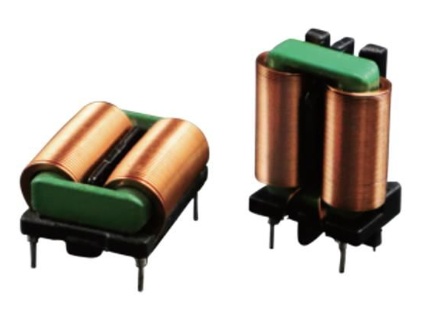

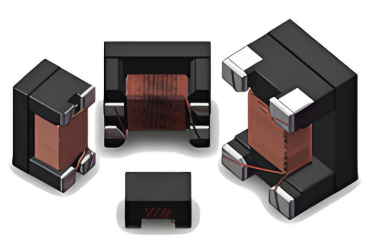

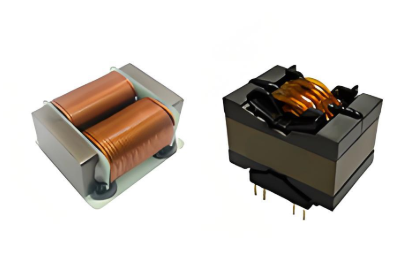

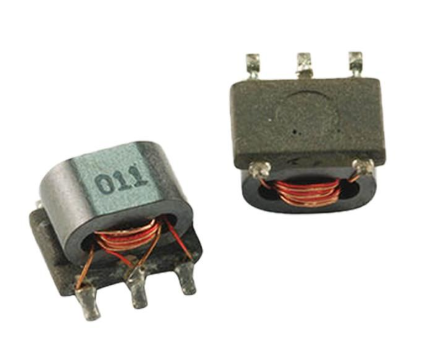

Ferrite Core Magnetic Rod Coil, High Current Through-Hole Magnetic Rod Coil, Iron Core Common Mode Choke Inductor, SMD Ferrite Core Choke Inductor, Through-Hole, High Current, Low Profile

Common Mode Choke Inductor, SMD Ferrite Core Choke Inductor, Through-Hole, High Current, Low Profile High-Current Power Inductors | Low-Loss, High-Efficiency Designs for Switching Power Supplies

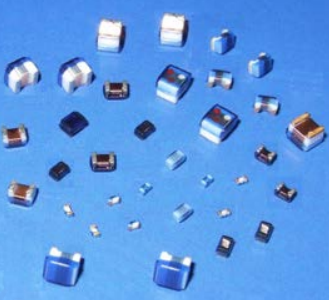

High-Current Power Inductors | Low-Loss, High-Efficiency Designs for Switching Power Supplies Ceramic Inductor: High Frequency Ceramic Inductors for RF Applications

Ceramic Inductor: High Frequency Ceramic Inductors for RF Applications Ferrite Rod Inductor: High Saturation R-Bar Inductors for Power Circuits

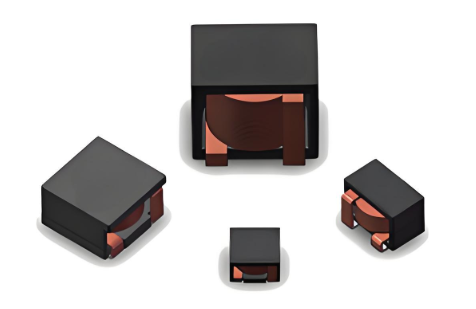

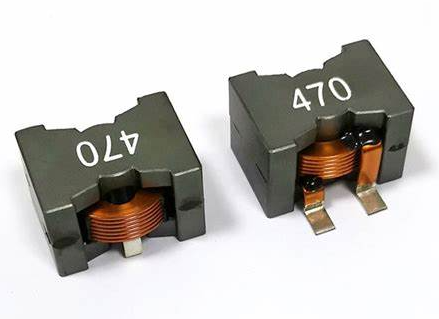

Ferrite Rod Inductor: High Saturation R-Bar Inductors for Power Circuits Chip Inductor: Surface Mount Chip Inductors for Compact Designs

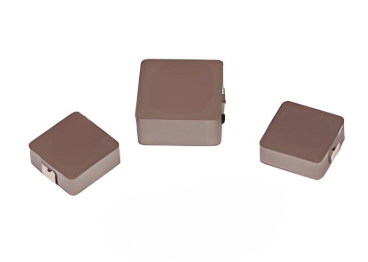

Chip Inductor: Surface Mount Chip Inductors for Compact Designs Molded Inductor: Durable Molded Inductors for Reliable Performance

Molded Inductor: Durable Molded Inductors for Reliable Performance PFC Inductor: Power Factor Correction Inductors for Improved Efficiency

PFC Inductor: Power Factor Correction Inductors for Improved Efficiency Flat Wire Inductor: High Efficiency Flat Wire Inductors for Power Applications

Flat Wire Inductor: High Efficiency Flat Wire Inductors for Power Applications Power Bead Inductor: High Current Power Bead Inductors for Efficient Filtering

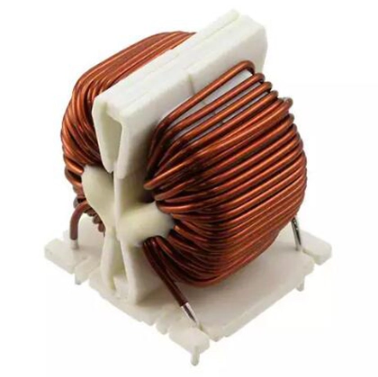

Power Bead Inductor: High Current Power Bead Inductors for Efficient Filtering Toroidal Inductors Colis

Toroidal Inductors Colis Wide Would Chip Inductors

Wide Would Chip Inductors SMD Flat Top Air Core Inductors

SMD Flat Top Air Core Inductors SMD Power Inductors

SMD Power Inductors High Current Power Inductors

High Current Power Inductors Flat Wire Inductors

Flat Wire Inductors

- What Are Flat Top Air Core Inductors?

What Are Flat Top Air Core InductorsFlat top air core inductors are a subset of air core inductors—coils wound without a magnetic core (just air or a non-magnetic former), often with a flattened top...

- What Are Rod Choke Inductors?

What Are Rod Choke InductorsFirst, a quick refresher: Rod choke inductors are a type of inductor with a coil of wire wound around a straight, rod-shaped core—often made of ferrite or iron powder. Th...

- High Current Power Inductors: Design and Applications

High current power inductors are heavy-duty components built to handle significant current (think 10 A to 100s of A) while storing energy, filtering signals, or managing power in demanding systems. Un...

- High Current Inductors: Key Components in Modern Power Electronics

High current inductors are indeed key components in modern power electronics, serving as the backbone for energy storage, filtering, and power management in systems pushing 10 A to hundreds of amps. F...

- Understanding the Performance Characteristics of High Current Power Inductors

Understanding the performance characteristics of high current power inductors is crucial for picking the right one and ensuring it thrives in your circuit—whether it’s handling 10 A in a small PSU...

- High Current Inductors: Innovations and Trends in Power Conversion

High current inductors are at the heart of power conversion, and recent innovations and trends are pushing them to handle more current (10 A to 500 A+), higher frequencies (up to 5 MHz), and tighter s...

- What Are Flat Top Air Core Inductors?

What Are Flat Top Air Core InductorsFlat top air core inductors are a subset of air core inductors—coils wound without a magnetic core (just air or a non-magnetic former), often with a flattened top...

- What’s Flux Coupling in a Transformer?

What’s Flux Coupling in a TransformerTransformers work by coupling magnetic flux between coils via a core (e.g., ferrite, iron). A "flux-coupled transformer" suggests one where this linkag...

- Are Balun Transformers Widely Accepted?

Are Balun Transformers Widely AcceptedYes, balun transformers (or baluns) are widely accepted and entrenched in electronics, particularly in RF and antenna systems. Here’s why:Proven Utility:Baluns ...

- What is Balun Transformers?

A balun transformer (or simply a "balun") is a specific type of transformer designed to convert between balanced and unbalanced electrical signals, as I mentioned earlier. The term "tra...

Inductor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000