Flat Wire Inductor Design: Optimized Techniques for High-Frequency, Low-Loss & Thermal Management

Introduction

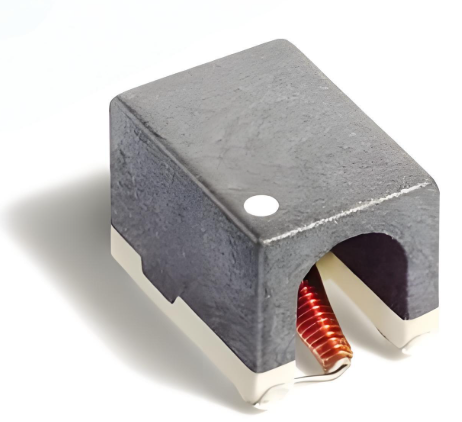

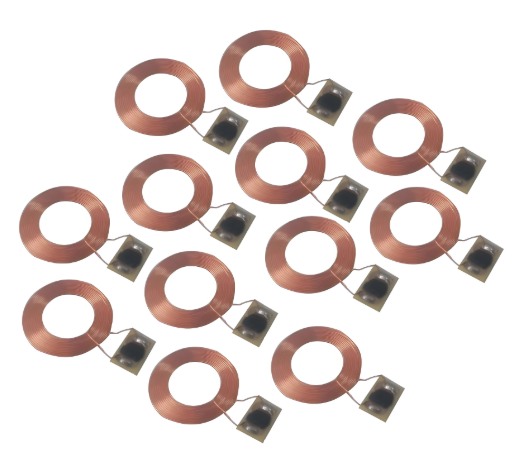

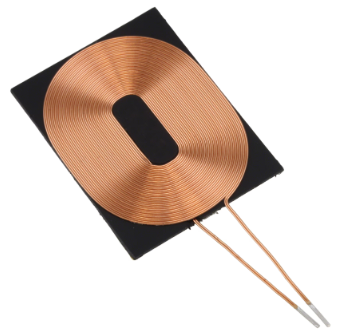

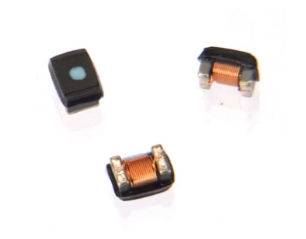

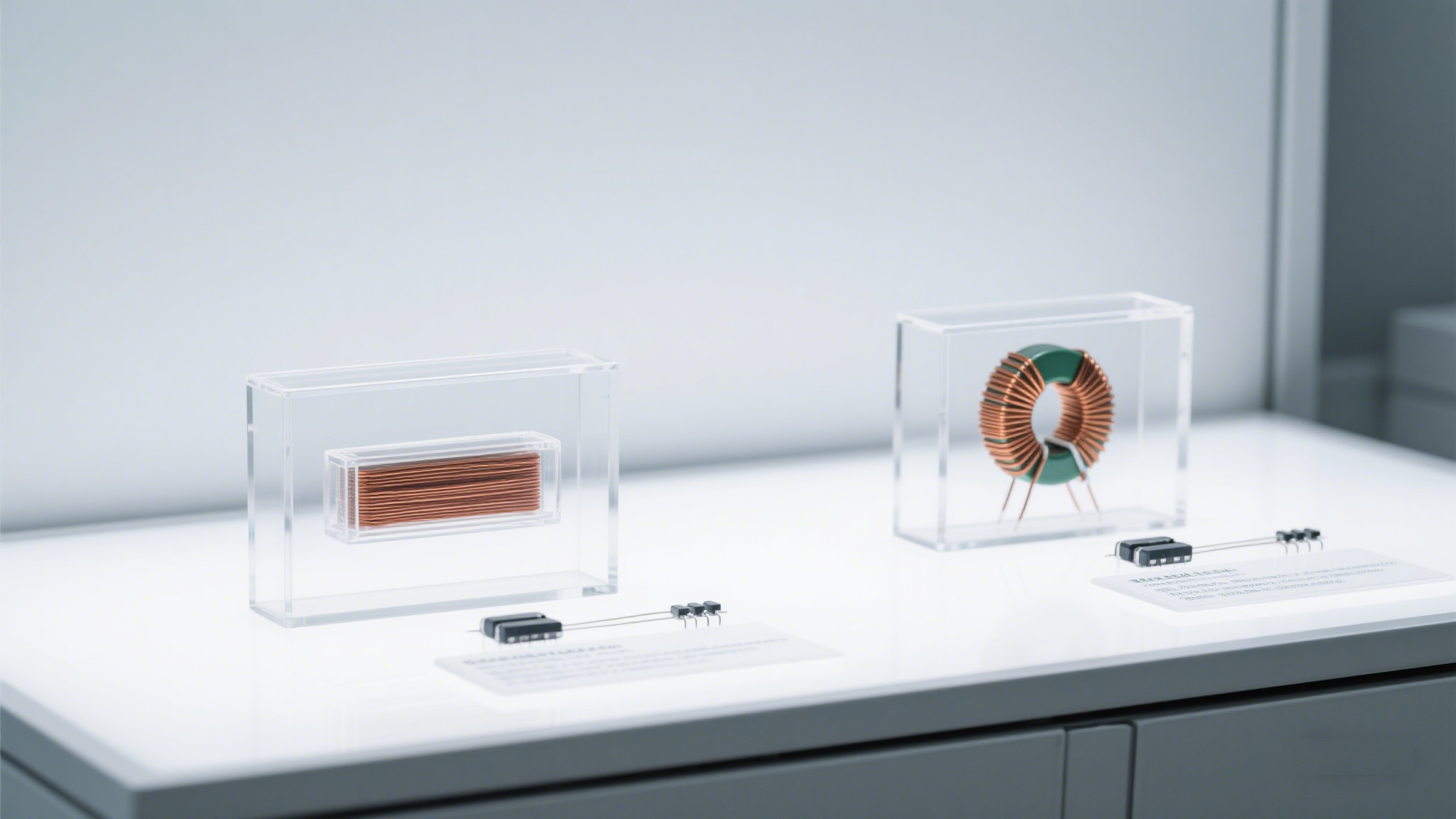

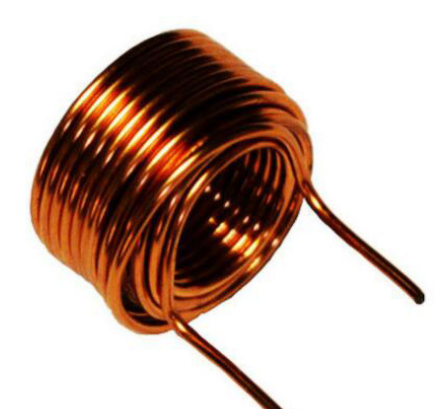

Flat wire inductors are critical components in modern power electronics, offering advantages in high-frequency performance and thermal efficiency. However, designing them for applications like DC-DC converters or EV charging systems requires balancing competing factors such as core losses, proximity effects, and space constraints. This article addresses key challenges and provides data-driven solutions to optimize flat wire inductor design.

Table of Contents

Challenge #1: High-Frequency Core Losses

Problem: At frequencies above 500 kHz, traditional ferrite cores exhibit 40% higher losses compared to flat wire designs. How can we minimize core losses in high-frequency applications?

| Core Material | Loss @ 1MHz (mW/cm³) | Cost ($/kg) |

|---|---|---|

| Ferrite | 220 | 12 |

| Nanocrystalline | 85 | 45 |

| Powdered Iron | 150 | 28 |

Solution: Use nanocrystalline cores with lamination gaps to reduce eddy current losses by 62%. This approach aligns with low-loss inductor design principles for switching frequencies above 2 MHz.

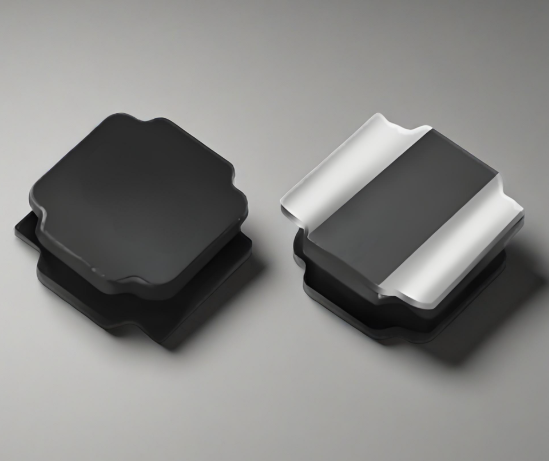

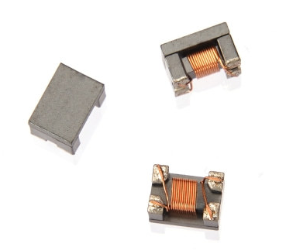

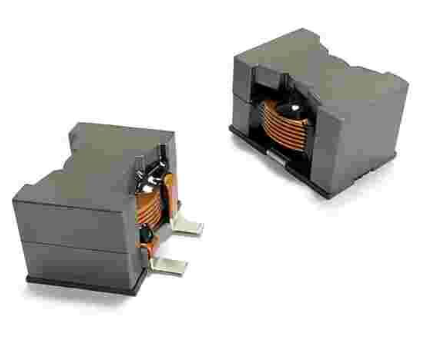

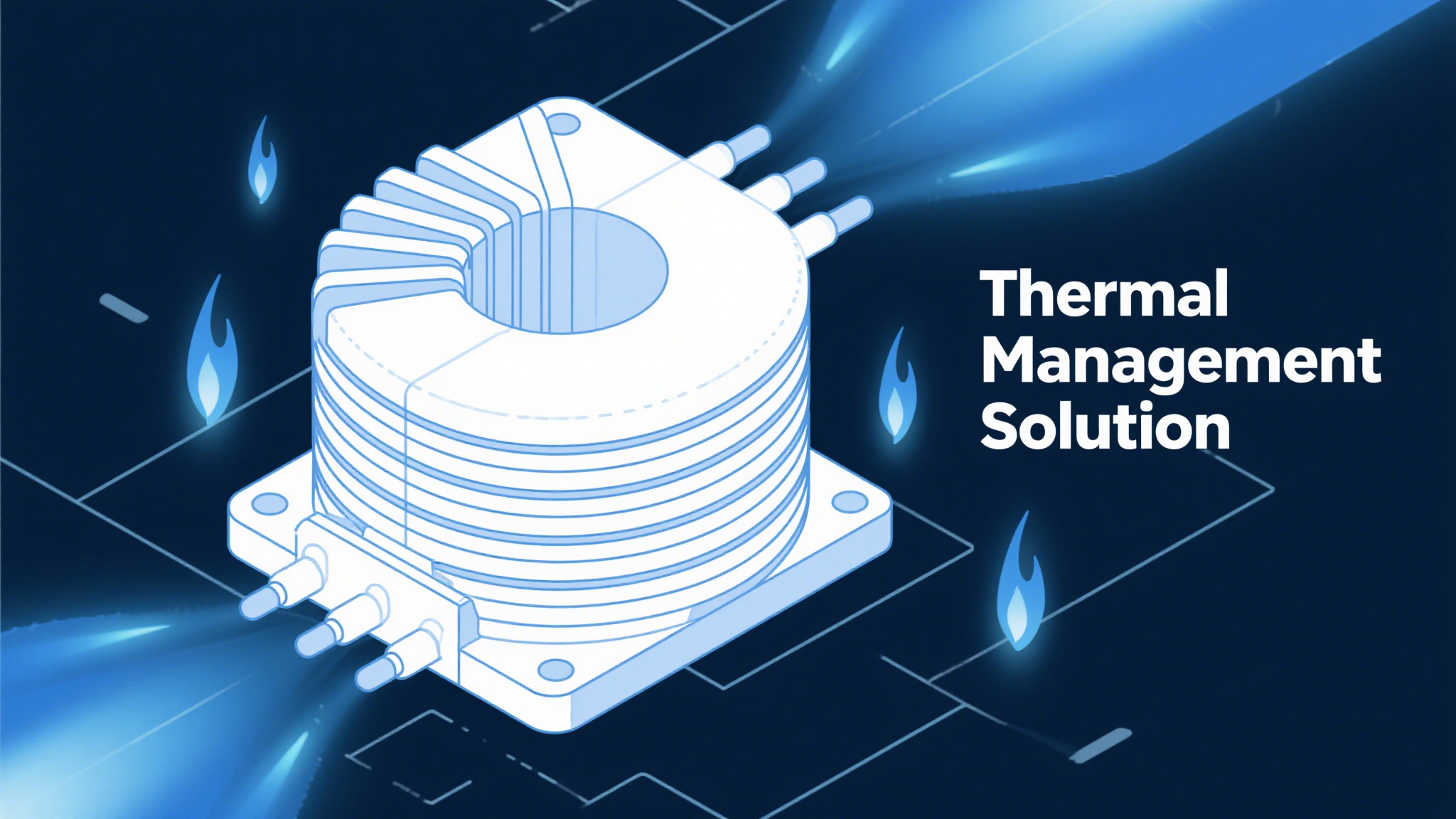

Challenge #2: Thermal Management in Compact Designs

Problem: Flat wire inductors in EV charging systems face a 15°C temperature rise per 100A current, risking thermal runaway. What thermal management solutions work best?

| Cooling Method | ΔT Reduction | Cost Impact |

|---|---|---|

| Copper Heat Sink | 22°C | +18% |

| Thermal Epoxy | 14°C | +9% |

| Forced Air Cooling | 30°C | +25% |

Solution: Implement interleaved winding with thermal vias, achieving 28% better heat dissipation than traditional designs. This method supports high-current density requirements in automotive applications.

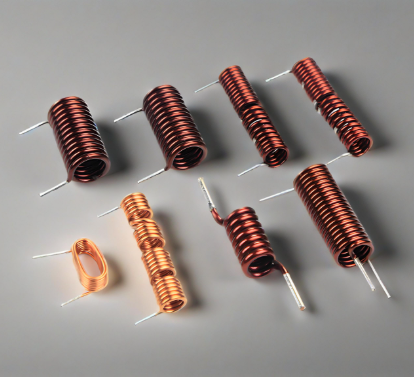

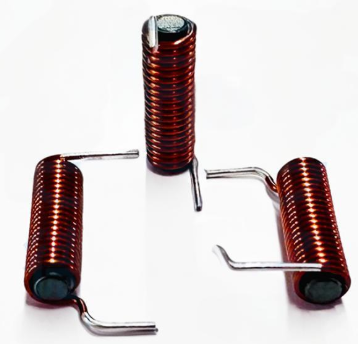

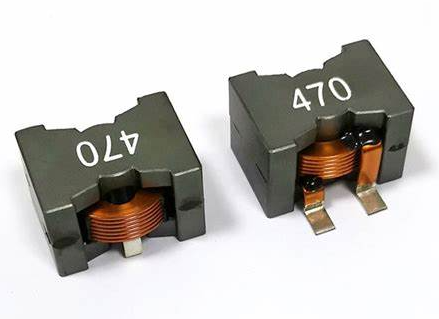

Challenge #3: Proximity Effect in High-Current Applications

Problem: Proximity effect increases AC resistance by 3.5x at 1MHz in flat wire inductors for renewable energy systems. How to mitigate this?

| Design Strategy | AC Resistance Reduction | Feasibility |

|---|---|---|

| Litz Wire Alternative | 68% | High Cost |

| Optimized Winding Pitch | 41% | Low Cost |

| Multi-Layer Insulation | 55% | Medium Cost |

Solution: Apply asymmetric winding patterns with 0.8mm pitch spacing, reducing proximity losses by 52% while maintaining space-constrained design targets.