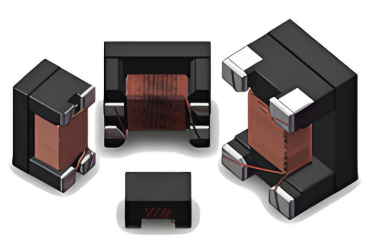

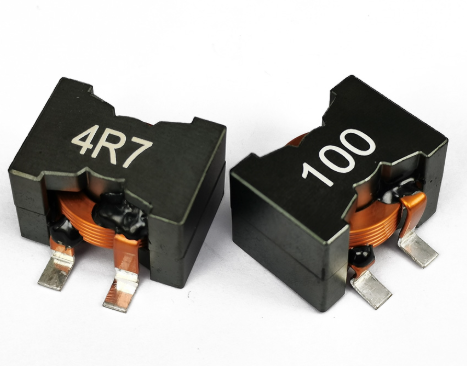

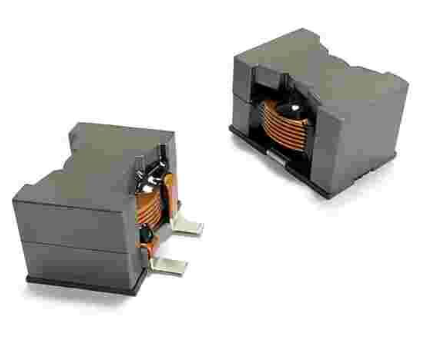

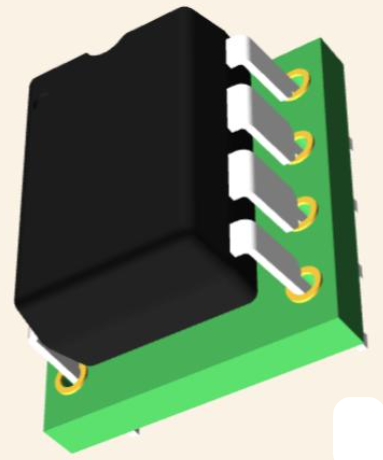

- Flat Wire vs Round Wire Inductors: Key Differences, Performance Comparison, and Best Applications for Power Electronics

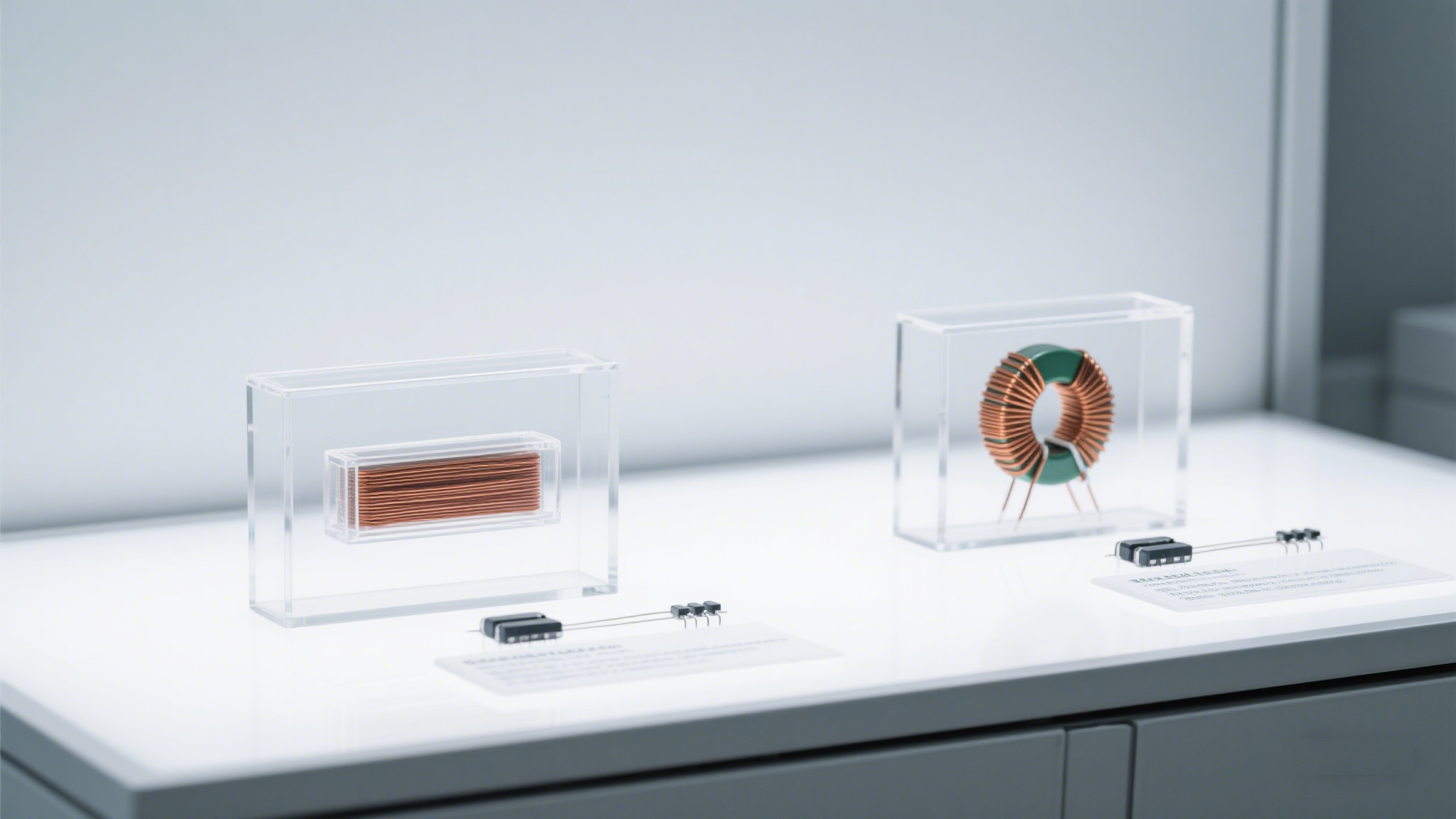

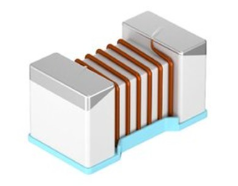

Introduction: Why Compare Flat Wire and Round Wire InductorsIn power electronics design, selecting between flat wire inductors and round wire inductors impacts system effi...

- Flat Wire Inductor Design: Optimized Techniques for High-Frequency, Low-Loss & Thermal Management

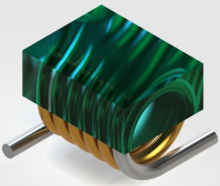

Flat Wire Inductor Design: Optimized Techniques for High-Frequency, Low-Loss & Thermal ManagementIntroductionFlat wire inductors are critical components in modern power electr...

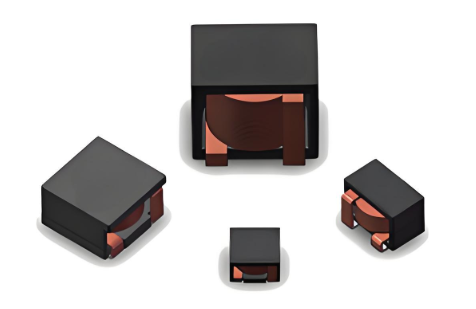

- High Current Inductors: Key Components in Modern Power Electronics

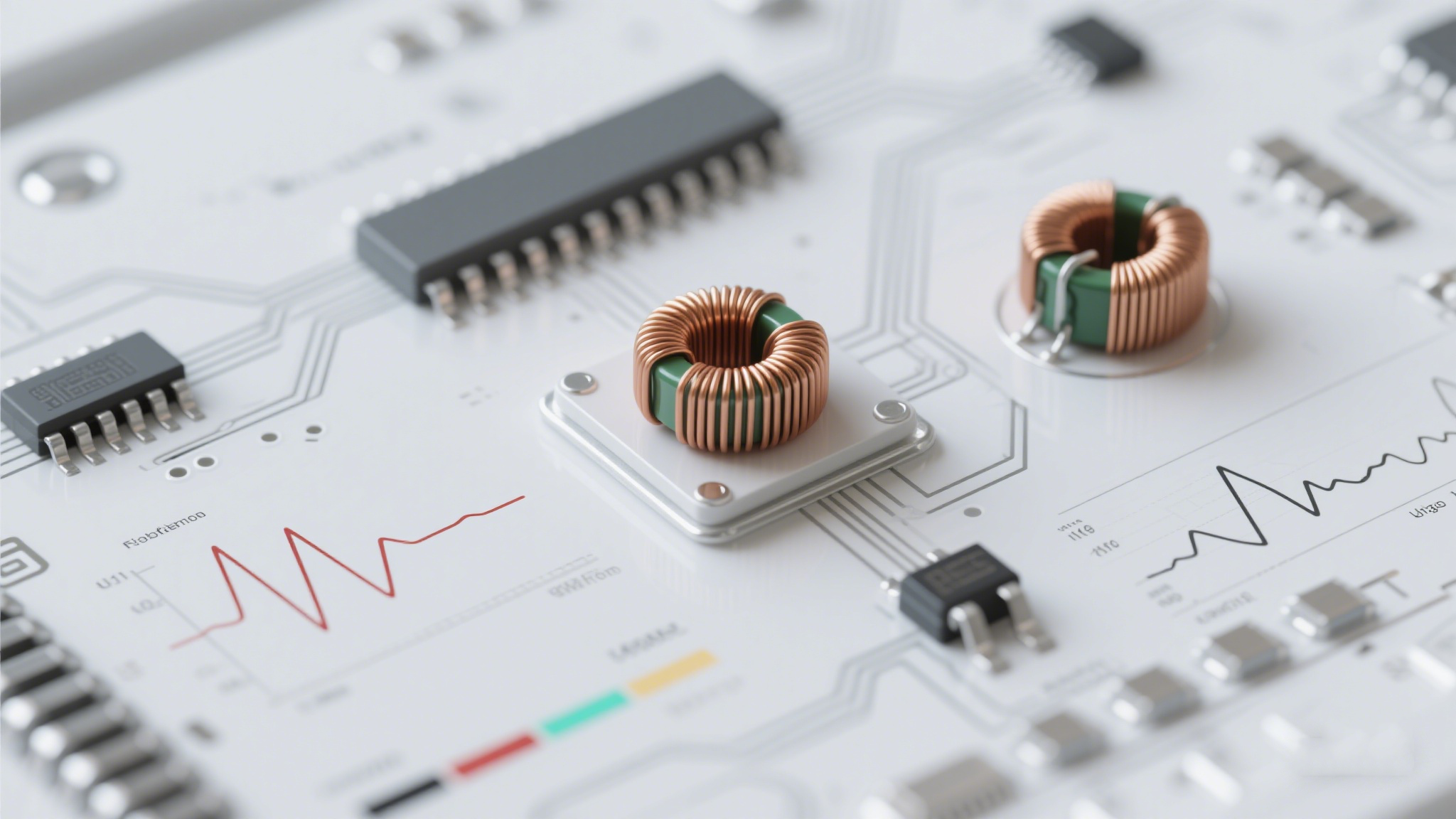

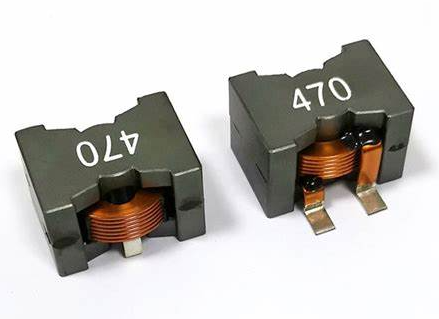

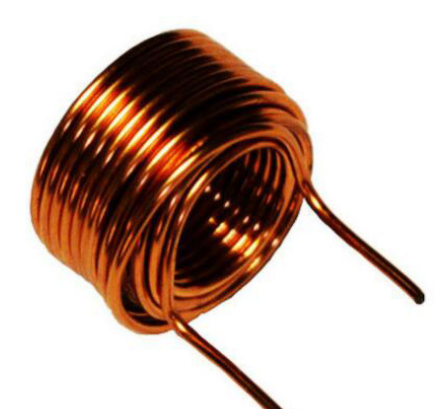

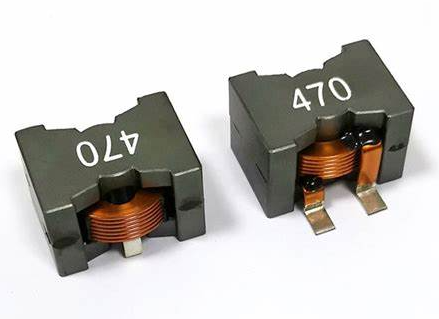

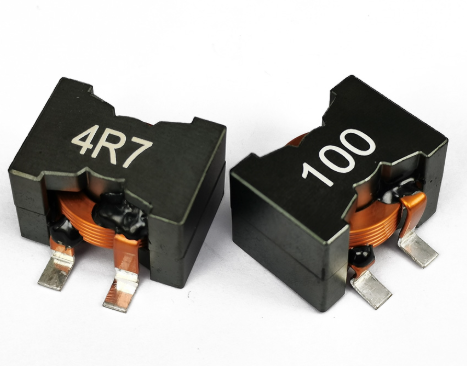

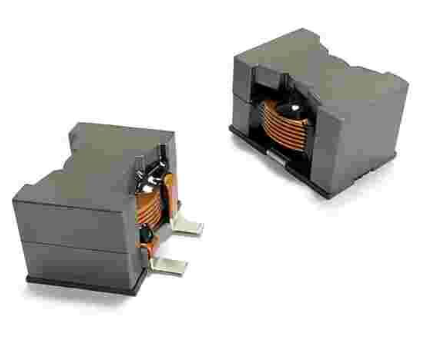

High current inductors are indeed key components in modern power electronics, serving as the backbone for energy storage, filtering, and power management in systems pushing 10 A to hundreds of amps. F...

- What Are Flat Top Air Core Inductors?

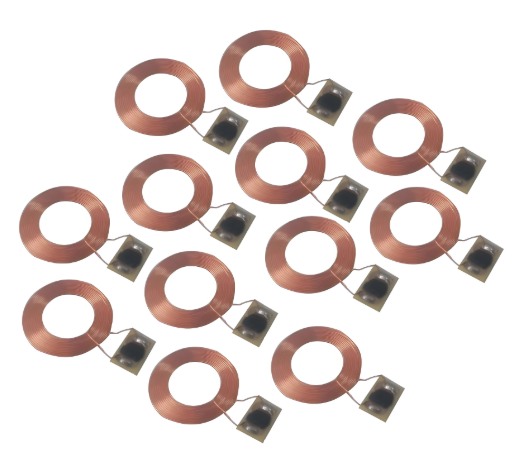

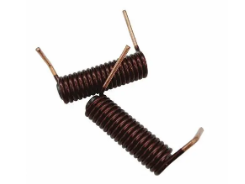

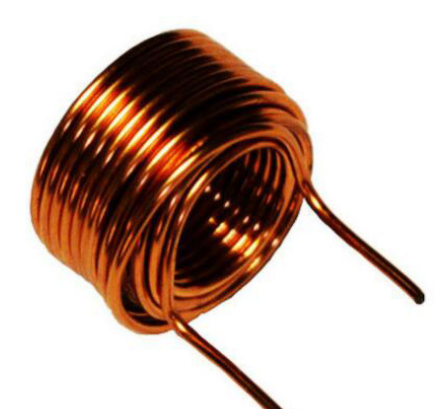

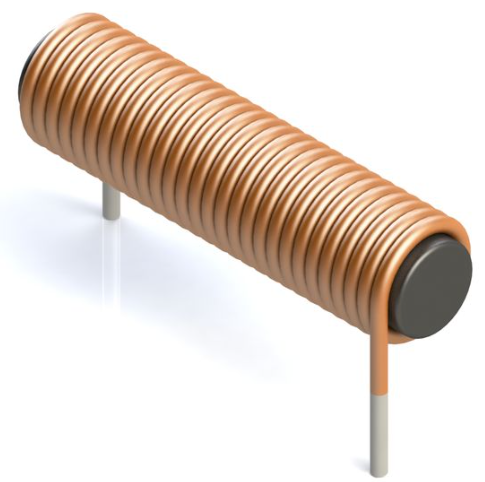

What Are Flat Top Air Core InductorsFlat top air core inductors are a subset of air core inductors—coils wound without a magnetic core (just air or a non-magnetic former), often with a flattened top...

- Understanding the Performance Characteristics of High Current Power Inductors

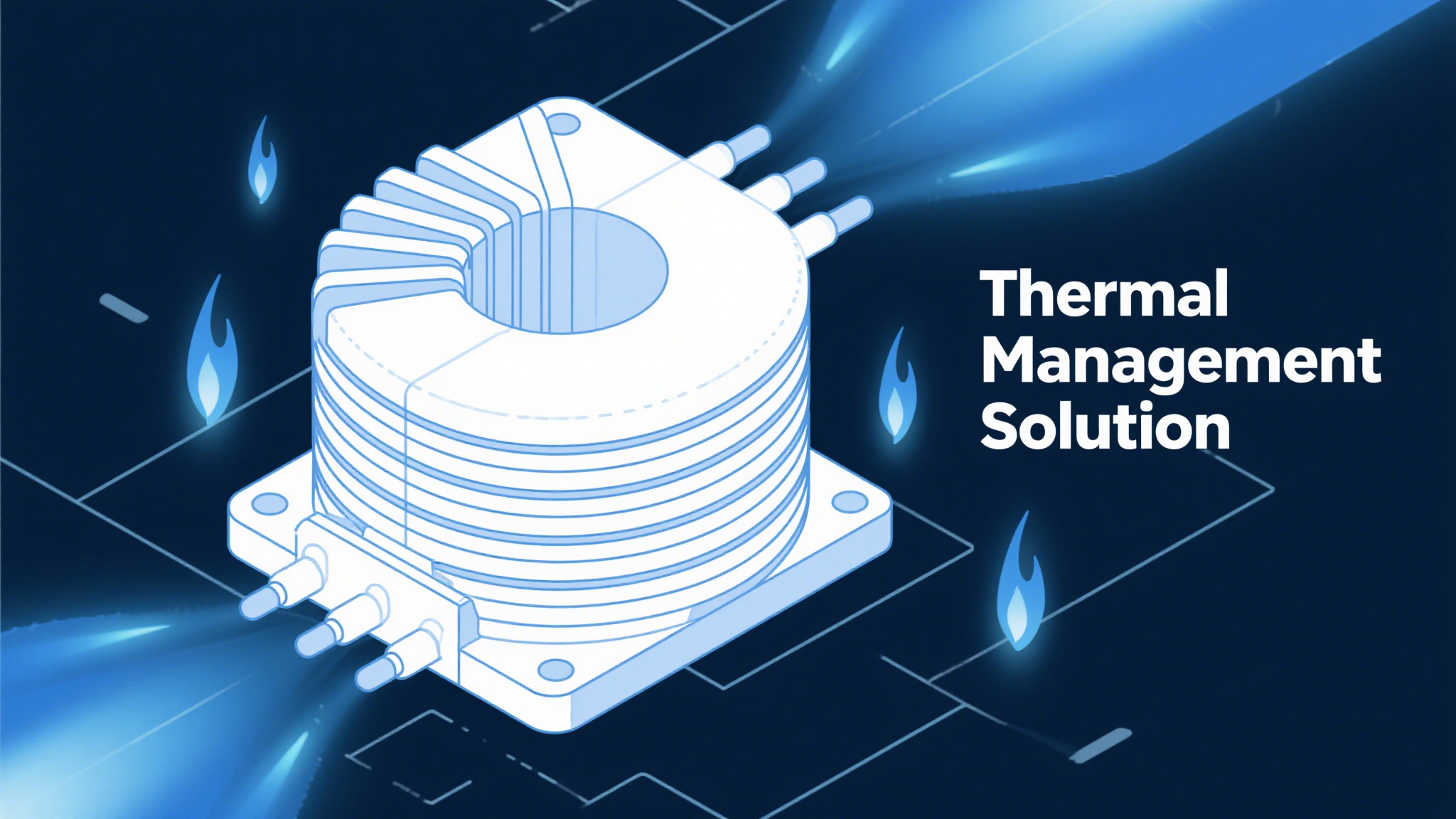

Understanding the performance characteristics of high current power inductors is crucial for picking the right one and ensuring it thrives in your circuit—whether it’s handling 10 A in a small PSU...

- Understanding the Differences Between Power Splitters, Dividers, and Combiners

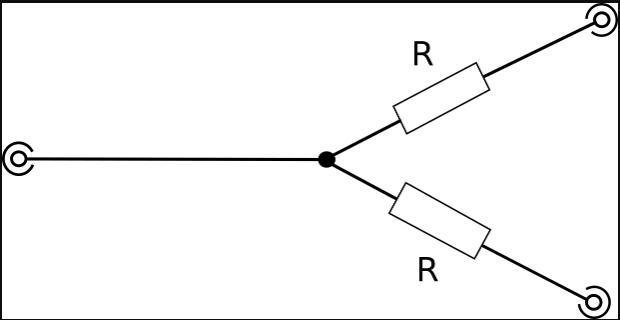

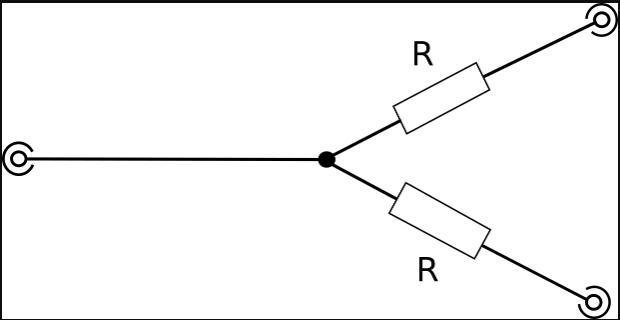

Core DefinitionsPower SplittersWhat: Devices that take one input signal and split it into two or more outputs, often implying a simple, equal division.Intent: Basic signal sharing across multiple path...

- High Current Power Inductors: Design and Applications

High current power inductors are heavy-duty components built to handle significant current (think 10 A to 100s of A) while storing energy, filtering signals, or managing power in demanding systems. Un...

- Exploring the Performance Characteristics of Directional Couplers in High-Frequency Systems

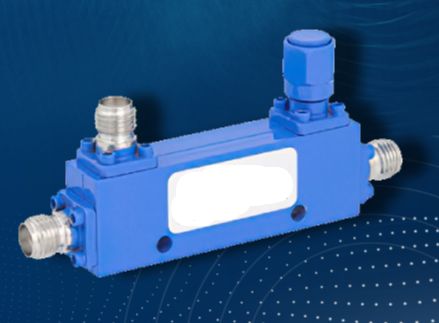

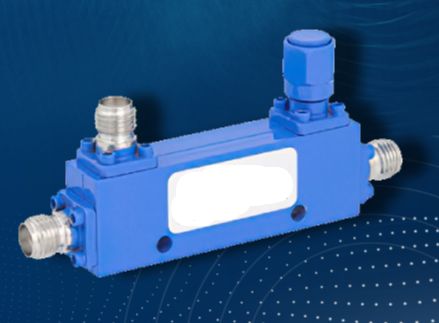

Exploring the performance characteristics of directional couplers in high-frequency systems (think RF, microwave, and millimeter-wave, from 1 GHz up to 100 GHz or more) reveals why they’re so critic...

- Applications of Power Splitters and Combiners in RF and Microwave Systems

Power splitters and combiners are workhorses in RF and microwave systems, enabling signal distribution and aggregation across a huge range of applications. From splitting a signal to feed multiple ant...

- Applications and Types of Directional Couplers in Communication Networks

Directional couplers are essential components in communication networks, widely used for their ability to split, combine, or sample signals while maintaining directionality. Below, I’ll outline thei...

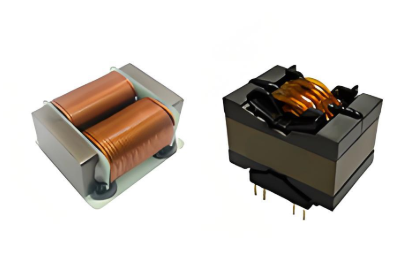

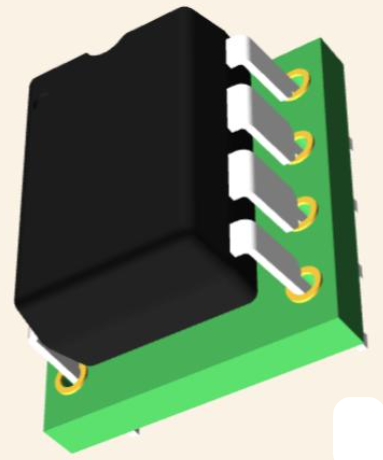

- Understanding Common Mode Chokes: Principles and Applications

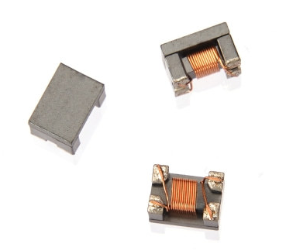

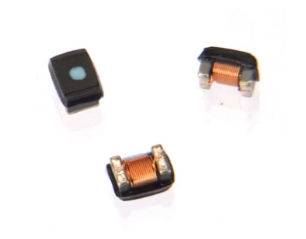

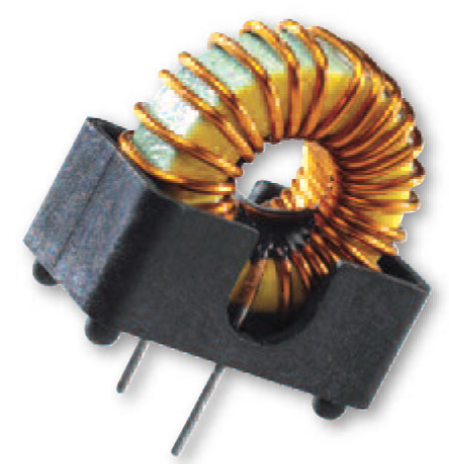

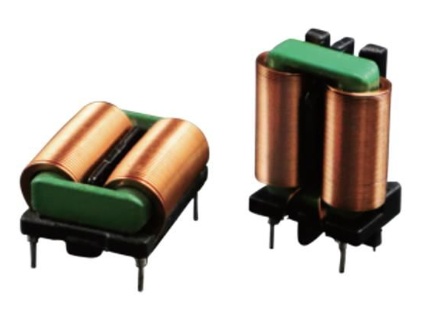

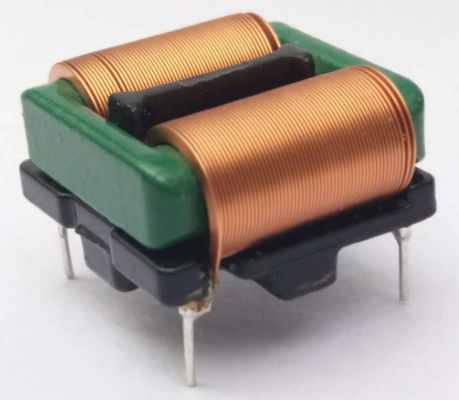

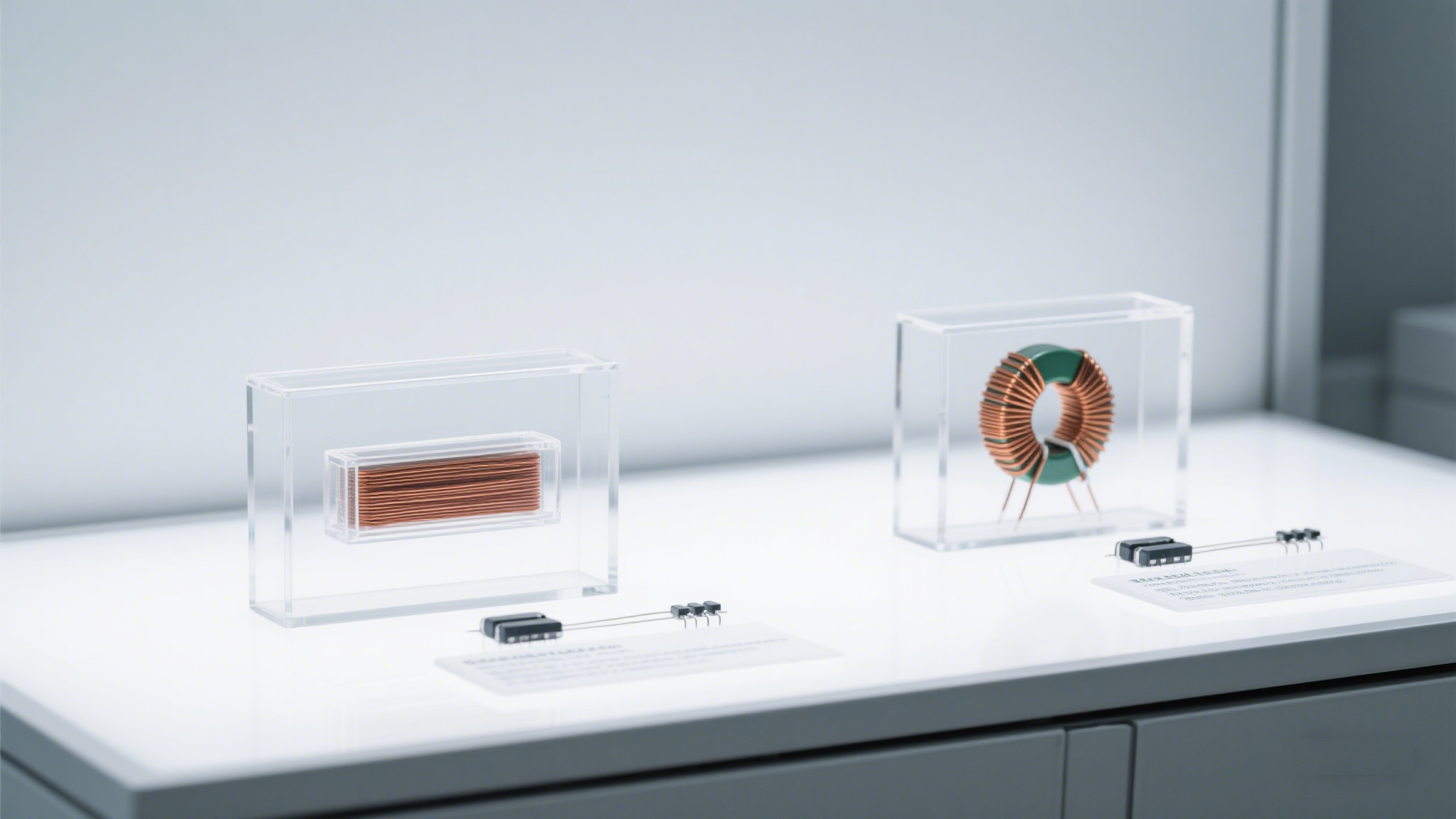

Common mode chokes (CMCs) are key players in RF, microwave, and power electronics, designed to tackle common mode noise—unwanted signals that appear simultaneously and in-phase on both lines of a di...

- High Current Inductors: Innovations and Trends in Power Conversion

High current inductors are at the heart of power conversion, and recent innovations and trends are pushing them to handle more current (10 A to 500 A+), higher frequencies (up to 5 MHz), and tighter s...

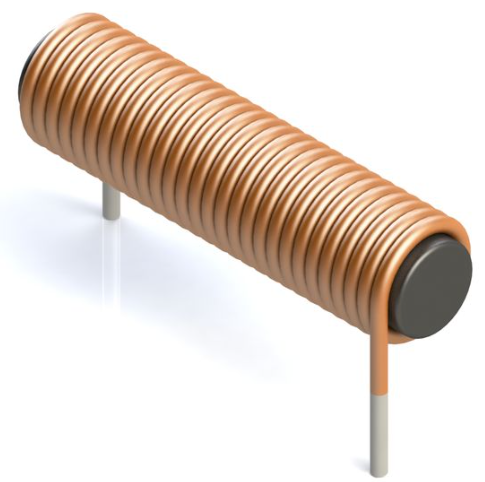

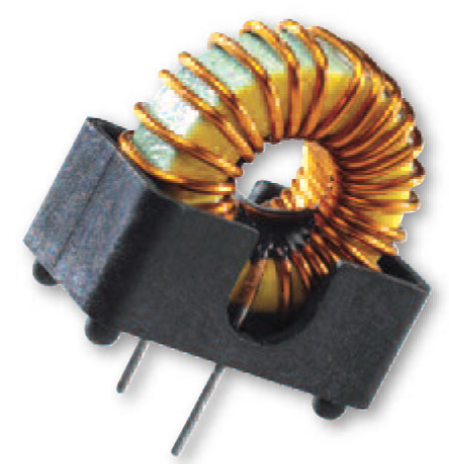

- What Are Rod Choke Inductors?

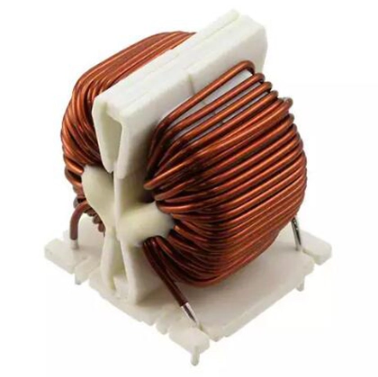

What Are Rod Choke InductorsFirst, a quick refresher: Rod choke inductors are a type of inductor with a coil of wire wound around a straight, rod-shaped core—often made of ferrite or iron powder. Th...

- Selecting the Right High Current Power Inductor for Your Circuit

Selecting the right high current power inductor for your circuit is about matching the component’s specs to your application’s demands—current, frequency, efficiency, size, and cost all play a r...

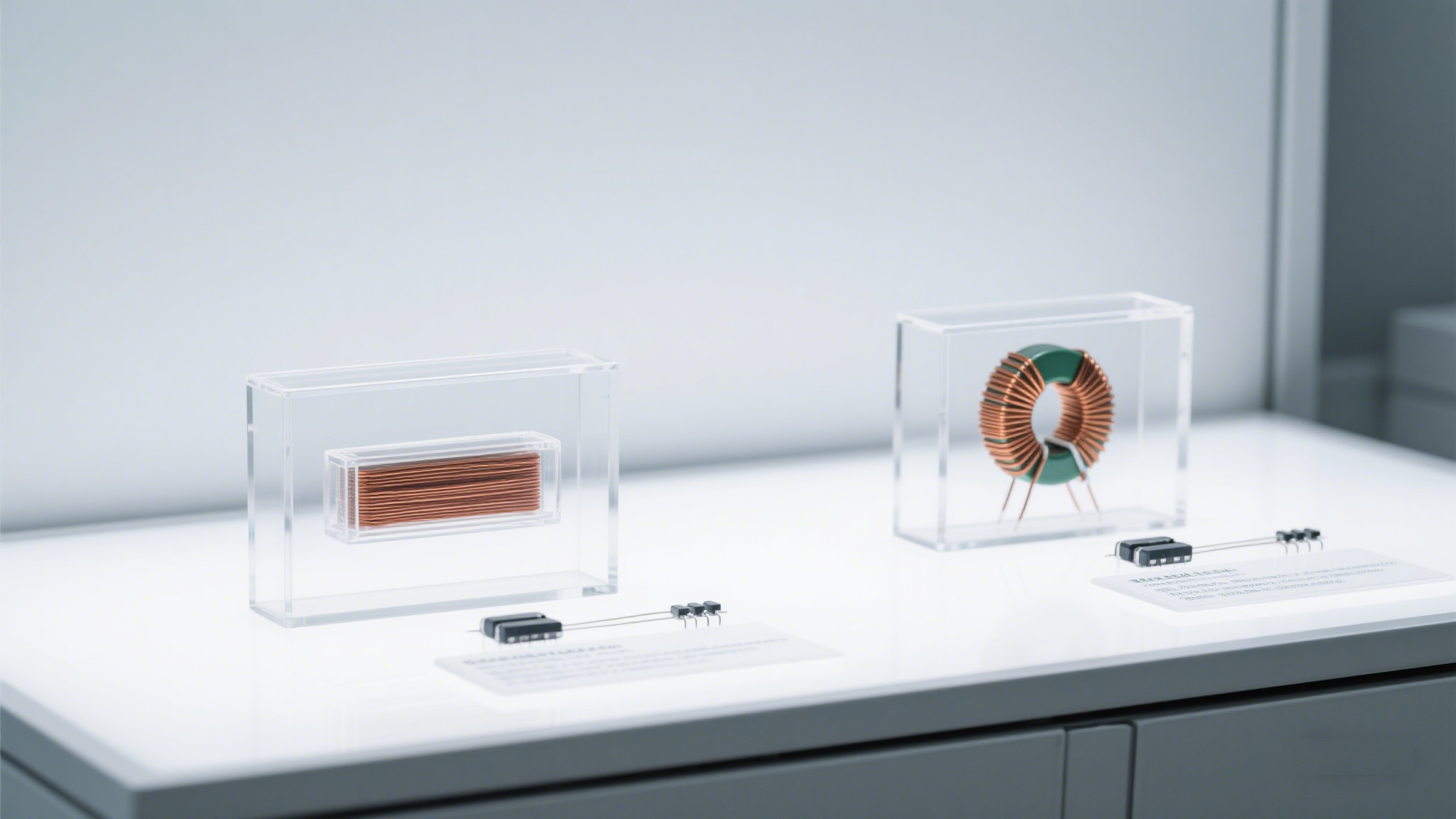

- Advancements in High Current Inductor Technology for Power Supplies

Advancements in high current inductor technology for power supplies have been driven by the relentless push for efficiency, compactness, and performance in modern applications like EVs, 5G infrastruct...

- Directional Couplers: Key Components for Power Monitoring and Signal Division

Directional couplers are indeed key components for power monitoring and signal division in communication systems. They’re versatile tools that enable precise control and analysis of signals without ...

- Power Splitters, Dividers, and Combiners: Essential Components for Signal Distribution

Power splitters, dividers, and combiners are indeed essential components for signal distribution in RF, microwave, and communication systems. They manage how signals are split into multiple paths or m...

- Common Mode Chokes in Power Supply Systems: Enhancing Signal Integrity

Common mode chokes (CMCs) are clutch in power supply systems for enhancing signal integrity, especially where noise can corrupt sensitive circuits or radiate into the environment. In these systems—t...

- Flat Wire vs Round Wire Inductors: Key Differences, Performance Comparison, and Best Applications for Power Electronics

Introduction: Why Compare Flat Wire and Round Wire InductorsIn power electronics design, selecting between flat wire inductors and round wire inductors impacts system effi...

- Flat Wire Inductor Design: Optimized Techniques for High-Frequency, Low-Loss & Thermal Management

Flat Wire Inductor Design: Optimized Techniques for High-Frequency, Low-Loss & Thermal ManagementIntroductionFlat wire inductors are critical components in modern power electr...